A Printing Guide to Custom Cardboard Boxes

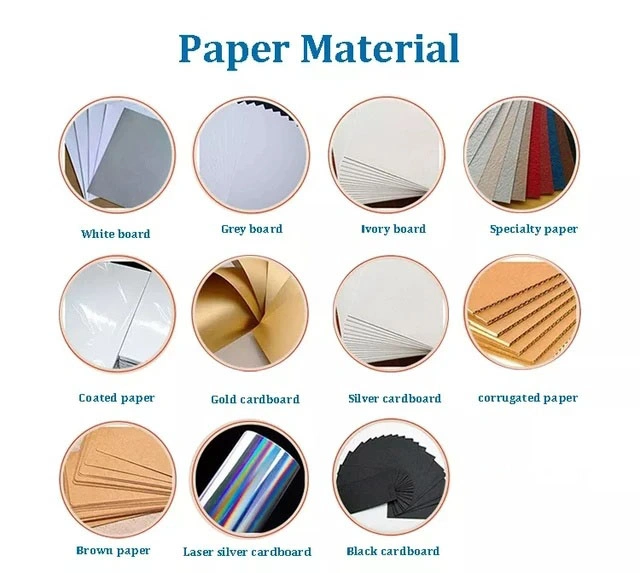

Understanding cardboard types and material selection

- B-Flute: Offers good strength and cushioning, ideal for smaller boxes and light-to-medium products.

- C-Flute: Has a good balance of strength and thickness, making it versatile for most applications.

- E-Flute: Thinner and smoother, perfect for high-quality prints and smaller, lightweight products.

| Product Weight | Recommended cardboard layers and thickness | Description |

| Under 1kg | 1-2 layers, 3-5mm | Lightweight products, lightweight with basic protection. |

| 1-10kg | 2-3 layers, 5-7mm | Medium-weight products, requiring adequate support and protection. |

| Over 10kg | 3-5 layers, 7-9mm | Heavy products, requiring high strength and good cushioning. |

- Fragile Items: For fragile products, multi-layer corrugated cardboard is ideal. You can also add inserts like foam or honeycomb paper for extra cushioning to prevent damage during transport.

- Moisture/Water Resistance: If your product needs extra protection from moisture or water, consider coated or moisture-resistant paperboard. This will improve the protective qualities of your packaging, especially in humid or rainy conditions.

- Long-Distance Shipping: For items that will be shipped long distances, consider using five-layer or seven-layer corrugated cardboard. These types provide better compression resistance and shock absorption, keeping your product safe during transport.

Printed methods for packaging boxes

Flexographic printing (flexo printing)

- advantages:

- Economical for large runs

- Highly efficient

- disadvantages:

- Not suitable for intricate designs

- Colors may not be as vivid or precise as other methods

Lithographic printing (offset printing)

- advantages:

- High-quality prints

- Great for intricate and multi-colored designs

- disadvantages:

- More expensive than flexographic printing

- Requires a longer setup time

Digital printing

- advantages:

- Cost-effective for small runs

- Great for vibrant colors and complex designs

- No printing plates required, saving on costs

- disadvantages:

- Ink quality may not be as durable as other methods

- Not suitable for some types of materials

Screen printing

- advantages:

- Highly durable and resistant to wear

- Great for large, simple designs with bold colors

- disadvantages:

- More labor-intensive than other methods

- Not ideal for detailed or multi-colored designs

UV printing

- advantages:

- Fast drying times

- High-quality prints with a glossy finish

- Suitable for a variety of substrates

- disadvantages:

- Expensive than other printing methods

- May not be suitable for all materials

Custom cardboard box design and print process

Design preparation

- Creating a dieline: A dieline is the blueprint of the cardboard box that shows where the folds, cuts, and creases will be. It ensures that the packaging fits perfectly and protects the product. This is the foundation of your design.

- Choosing the right color mode: Most designs use the CMYK color mode (Cyan, Magenta, Yellow, and Key/Black) to ensure color consistency across different devices and printers.

- Setting bleed lines: The bleed is the area outside the cut line that ensures your design elements like color blocks and images go all the way to the edge of the box. It prevents parts of the design from being cut off during the production process.

Choosing the right printing method

The printing process

- Aligning the design: Ensuring that the design is aligned correctly on the box is essential. Any misalignment could result in poor print quality.

- Choosing ink types: There are different types of ink used in printing, each with unique features. Here’s a brief overview of the most common types:

- Solvent-based ink: Known for durability and vibrant colors, typically used for flexographic printing.

- Water-based ink: Often used in digital printing, it is eco-friendly but may not be as durable.

- Oil-based ink: Commonly used in lithographic printing, providing rich, glossy results.

- UV ink: Cures instantly under UV light, providing high-quality, fast-drying prints.

Post-printing finishes

Coatings: gloss, matte, or soft-touch coatings protect the box and give it a polished look.

Lamination: this adds a protective layer to the box, making it more durable and resistant to damage.

Embossing and debossing: these techniques create raised (embossed) or recessed (debossed) designs for a tactile experience.

- Cutting: the printed material is cut into the box shape using a die-cutting process.

Quality control

Ensuring the final product meets your standards is essential. Quality control checks focus on color consistency, alignment, and material integrity. Here’s what’s typically checked:

Color consistency: Ensuring that the printed colors and logo match the design specifications across all boxes.

Alignment accuracy: Checking that the design aligns perfectly with the box’s edges.

Durability testing: Conducting friction and compression tests to confirm that the box will withstand handling and transportation without damage.

- Print quality inspection: Verifying print precision, alignment, and ensuring there are no defects like smudging or misprints.

Practical tips for improving print quality

Sustainable packaging trends

Cost breakdown of custom box printing

| Factors | Impact Explanation |

| Box Size | The larger the size, the larger the unfolded area, leading to higher material and printing costs. |

| Box Materials | More layers and better quality increase the unit price. |

| Print Artworks | Multiple colors and special processes increase printing costs. |

| Order Volume | Large orders can help spread out the plate-making and die-cutting costs. |

| Processing Complexity | Processes like slotting and folding increase labor and equipment costs. |

Common printing problems and solutions

How to choose the right packaging supplier

Packaging design and customer experience

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.