In this article you will learn

- What is kraft paper packaging

- When should you use kraft paper instead of coated board?

- What is a kraft board used for?

- Barrier solutions for food kraft paper packaging

- Customized options for printing, varnishing, lamination and construction

What is kraft paper packaging?

What is kraft paper made of?

Kraft paper is made from wood fibers such as spruce and pine. Wood chips are digested with white liquor (sodium hydroxide and sodium sulfide) to remove lignin and retain the long fibers. Unbleached paper retains its brown color and offers the highest strength. Bleached paper produces a whiter color and is easier to print, but with a slight decrease in strength. Therefore, the most durable grade is often brown, unbleached kraft paper.

| Kraft Paper Type | Fibers / Treatment | Typical Properties | What It Means for You |

|---|---|---|---|

| Unbleached Kraft Liner (KLB) | Long fibers, unbleached | High tear/burst resistance | Shipping strength with a natural brown look |

| Recycled / Test Liner | Mixed recycled fibers | Lower strength, more color variation | Lower cost; suitable for light loads |

| Sack Kraft Paper | Extensible, high TEA | Excellent tear resistance | Best for heavy-duty powder/granule bags |

| Bleached Kraft | Bleached treatment | Smoother surface | Cleaner print quality for retail cartons |

| Coated / Laminated Kraft | Coating or PE/aluminum lamination | Better barrier and print performance | Harder to recycle; use only when necessary |

- If you need waterproof performance, you should refer to the Cobb 60 index. The lower the Cobb number, the more water-resistant it is.

- Does it need to be stacked for transportation? Refer to the ECT (Edge Compression Test) to select the one that suits you. If your product has sharp edges, you’ll need to pay attention to the Mullen (burst resistance) rating.

- If your environment is humid, moisture will seep into the carton over time, reducing its protective strength. It is recommended that your paper moisture content be controlled at 6–8%.

Click here to learn more about printing methods for cardboard boxes.

What are the benefits of kraft paper packaging?

- High strength/cost-effectiveness: Long fibers provide better tear and burst resistance.

- Printing adaptation: Line drawings, logos, logos, and designs with more white space are better.

- Stable supply: Globally standardized grades ensure on-time delivery without delays to your packaging delivery.

- Low defect rate: Brown surface shows no scratches.

What is a kraft board used for?

- E-flute mailing box: KLB 200gsm / Test 180gsm, E-flute, ECT ≥ 32.

- Subscription Box: EB double tile, uncoated face paper, water-based matte finish.

- Export heavy cargo: BC double tile, ECT ≥ 44, and BCT verification after loading.

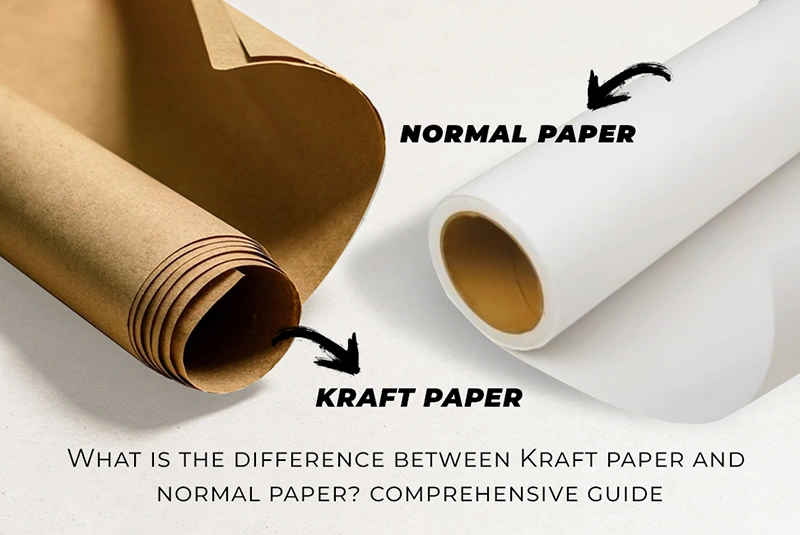

What is the difference between kraft paper and ordinary cardboard?

- For high stacking strength, ECT>40 or above is recommended.

- For exquisite and strong folding boxes, SBS/double-coated sheets are recommended.

- Focus on high tear/burst strength? Consider kraft paper.

Customization options for kraft paper

Coating/Surface treatment: Water-based matte/light gloss for enhanced wear resistance. Lamination is not necessary.

Barrier: For food or grease, place a food-grade inner bag first. For oil resistance, consider a PFAS-free oil barrier or a spot PE coating. Keep the plastic content to less than 5% to facilitate recycling.

Structure: mailing bags, sleeves, flap boxes, E/B/EB, double corrugated boxes for export of heavy goods.

Self-assessment checklist: is kraft paper right for you?

- The product is dry, non-oily → suitable.

- Brand accepts natural brown style → suitable.

- Suitable for transport in non-cold chain and non-high humidity environments → or after adding inner bags or light barriers.

Laboratory recommendations: Cobb, ECT/Mullen, BCT, and drop tests are required. Arrange small batch orders under normal production conditions before mass production.

Kraft paper packaging trends in 2025

- Better barrier paper: Try barrier paper with cowhide first, then consider lamination.

- Stronger heavy bag paper: High TEA reduces bag breaks during filling.

- Clearer environmental labeling: FSC/PEFC and recycling instructions are more standardized.

FAQs

Uncoated kraft paper is widely recyclable, its fiber is renewable and it is biodegradable. You can ask your supplier to provide FSC/PEFC reports.

Original kraft paper, recycled kraft paper, bag kraft (with wet strength/high TEA), white kraft paper, coated/laminated kraft.

Wood pulp paper made using the Kraft process. White liquor is delignified, retaining long fibers, resulting in high strength.

Conclusion

2) Determine the face paper and fluting according to BCT.

3) Print proofs including barcodes.

4) Conduct humidity and drop tests.

5) Reduce costs by customizing sizes and reducing bulk.

About XiangGe Package

We provide customized kraft paper packaging for global brands. We can match the face paper/fluting profile to your specific needs, perform ECT/BCT/Cobb testing, and optimize printing performance on brown substrates. We also offer FSC sourcing and water-based coating solutions.

Want to get a kraft paper box sample quickly? Send us your drawings and requirements. We’ll provide 2-3 feasible solutions and proofs.

Last updated: August 2025

External links: