Custom shipping boxes factory

- Sustainable: FSC certified recycled corrugated cardboard, 100% recyclable cardboard, and biodegradable ink.

- Easy customization: Die cut customization of size, material, thickness, and box shape.

- High production capacity: XiangGe produces 1 million boxes per day.

- Classified by layers: single, 3, 5, 7 flutes, and overweight boxes.

Know what you’re shipping. Measure your product and check weight and fragility. Decide if it ships alone or with others.

Pick the right box size. Add a little extra space for inserts. Avoid oversized boxes to save on shipping.

Choose the right types:

Single-wall: for light products.

Double-wall: for medium to heavy products.

Triple-wall: for heavy or fragile goodsAdd your branding. Send your logo. Choose box colors (inside and outside), Add custom text (website, social icons, messages)

Pick a printing method

Flexo: low-cost, basic colors.

Digital: full color, good for small runs.

Offset: high quality, best for large volumeAdd extra features (optional)

Matte or glossy finish.

Foil stamping.

Spot UV coating.

Custom inserts or dividers

How to customize shipping boxes

What size cardboard shipping boxes do you need?

This depends primarily on the size and protection requirements of your product. The shipping boxes should be slightly larger than the product itself to allow for adequate cushioning to prevent damage during transit.

Small boxes: 8 x 6 x 4 inches (20 x 15 x 10 cm) are suitable for small, lightweight items such as electronics and small accessories.

Medium boxes: 18 x 14 x 12 inches (46 x 36 x 30 cm) are suitable for larger and smaller appliances, clothing, and multi-unit packaging.

Large boxes: 24 x 18 x 18 inches (61 x 46 x 46 cm) are suitable for larger or heavier items such as furniture and household appliances.

Oversized boxes: 24 x 24 x 24 inches (61 x 61 x 61 cm) or larger are suitable for bulky or bulk shipments.

Before selecting a specific size, measure the length, width, and height of your product and select appropriate padding based on its value and fragility to ensure its safe transport.

Wholesale affordable shipping boxes

In today’s booming online retail and e-commerce landscape, we help you get your products to your customers safely and securely. We do this by providing innovative and sustainable custom shipping boxes solutions. Our shipping boxes are used for a wide range of products, including food, jewelry, clothing, electronics, glass, bottled goods, furniture, wine, plants, shoes, and golf clubs.

Custom corrugated shipping boxes

You can customize various materials, sizes, structures, printings, additional inserts to get the one that best meets your needs.

- Corrugated materials

- Thickness / Strength

- ECT

- Printing

Corrugated Materials

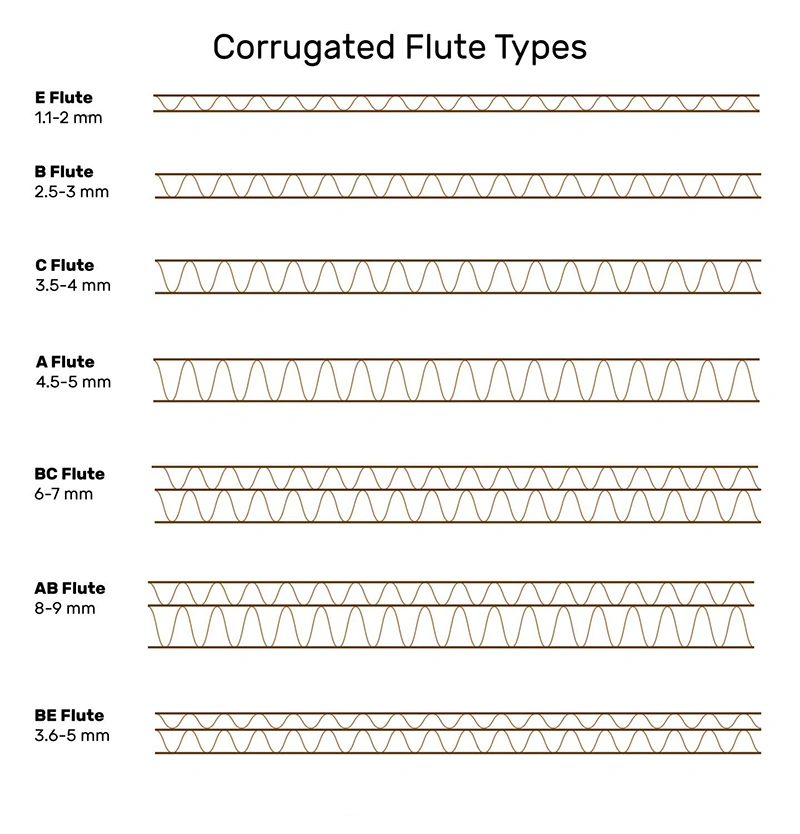

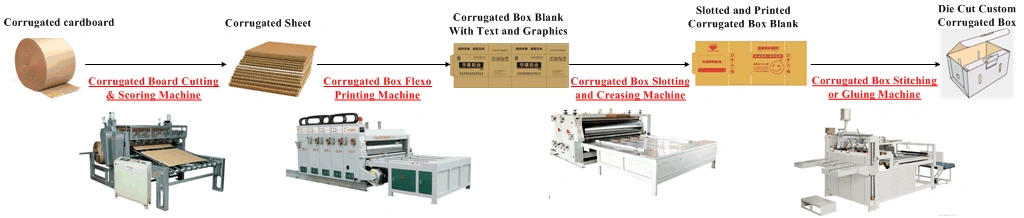

Corrugated cardboard consists of one or more layers of corrugated core paper and face paper. Common types of corrugated boxes are as follows:

A Flute: 4.5~5 mm thick, the thickest, with good cushioning performance and stacking ability, suitable for fragile products or products with high stacking strength requirements.

B Flute: 2.5~3 mm thick, low thickness, more teeth, good compressive strength and surface flatness, suitable for printing. Commonly used in consumer goods, canned foods, etc.

C Flute: 3.5~4 mm thick, performance between A flute and B flute, is a common transport packaging flute type, with a wide range of uses.

E Flute: 1.1~2 mm thick, extremely thin flute type, flat surface, excellent printing effect, commonly used in display boxes and gift boxes.

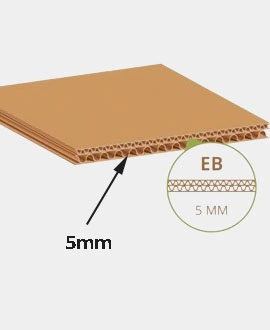

Of course, many people choose double corrugation: AB corrugation, BC corrugation, EB corrugation, cushioning performance and printing effect are better.

Thickness / Strength

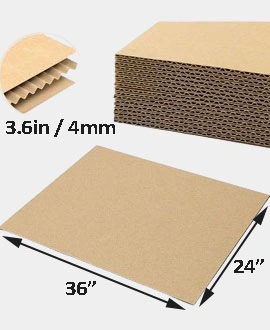

3mm, 4mm and 5mm are the most common shipping box thicknesses. 3mm thick B-type corrugated boxes are lightweight and have a smooth surface, while 4~5mm C-type corrugated boxes provide stronger protection.

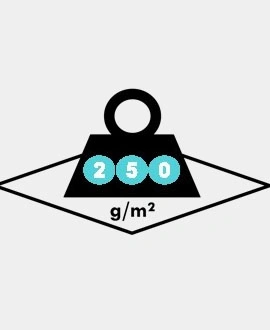

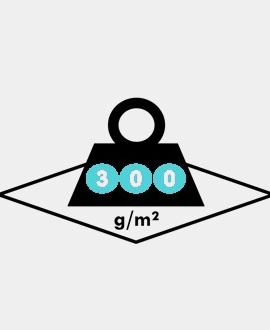

The heavier the paper weight, the thicker it is and the stronger it is.

250gsm is economical and suitable for cost-sensitive or lightweight products. 300gsm is the standard weight, which strikes a good balance between strength, appearance and cost. 350gsm paperboard has good tear and fold resistance and better printing effect.

Learn how different mailer box materials affect their durability. →

3mm thick paperboard

Corresponding to B flute single corrugated cardboard.

4mm thick paperboard

Corresponding to C flute single corrugated cardboard.

5mm thick paperboard

Corresponding to thinner double corrugated board, such as EB flute.

250 grams cardboard

Transport packaging for lightweight products.

300 grams cardboard

Suitable for most common transport packaging.

350 grams cardboard

Suitable for heavier items.

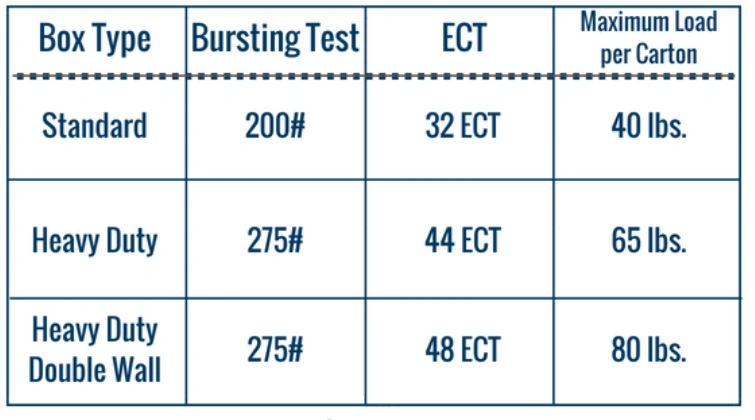

Edge Crush Test - ECT

The maximum pressure that corrugated cardboard can withstand is a key indicator of the stacking strength of cartons. The unit is pounds per inch or kN/meter. Common grades are 32, 44, 48, and 51 ECT. It directly affects the safety of your products during transportation and warehousing.

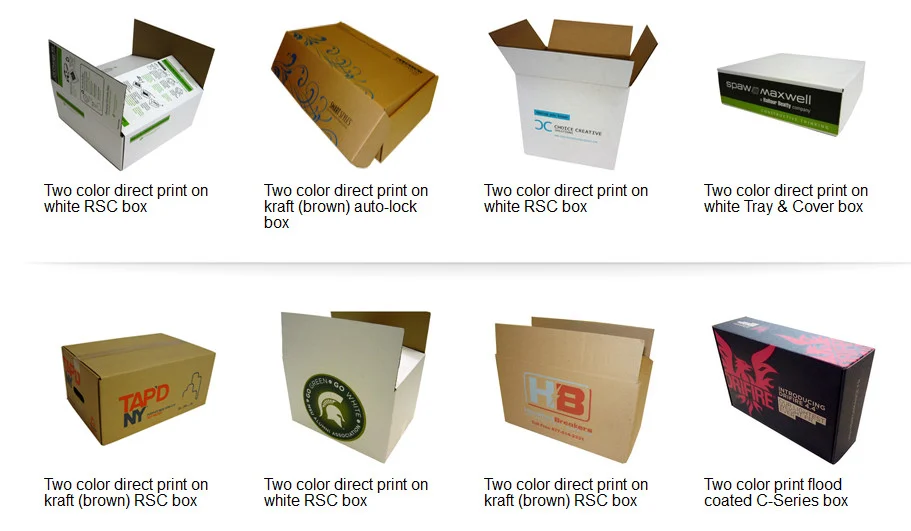

Printing Sides

Shipping box allows you to print any side to show your brand and packaging information. It can be printed on the outside, inside, full, or no printing.

Get shipping moving boxes today

Fill in your basic information for standard or heavy duty shipping boxes, and our team will contact and design it.

Why choose us to custom cardboard shipping boxes

When you need to ship extra-large, insulated, or irregularly shaped items, choosing the right shipping boxes is crucial. Here are some reasons to choose our shipping boxes:

Our corrugated shipping boxes are made from heavy-duty, high-strength corrugated cardboard, such as double- or triple-wall construction. This effectively prevents collapse or damage during transport and stacking.

Our box designs offer additional corner and bottom support to ensure overall structural stability.

We offer standard shipping box sizes and can customize them to meet your specific product size and weight requirements, ensuring a perfect fit.

We can also perform high-quality printing to display your logo, branding, or operating instructions, turning your shipping box into a mobile billboard.

How to work with us

- Express your shipping box needs. Your product type, size, shape, and weight. At the same time, your overall brand image and printed content.

- Determine your shipping box budget, including design costs, box prices, and additional fillers.

- Confirm the printing method. There are 3 common types of printing: offset printing, flexographic printing, and special printing.

- Does your box need paper coating? Appropriate coatings can improve the appearance of the packaging, such as matte, glossy, AQ coating, and UV coating.

- Create die-cut template. Transfer the designed drawings to the structural template.

- Create a prototype shipping box. We will complete the production of the shipping box sample within 1 to 3 working days and send it out for your confirmation.

- Finally, production and shipping. After everything is completed, your product packaging can be put into mass production.

Why are our clients saying

Since working with XiangGe shipping boxes, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The shipping boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of XiangGe shipping boxes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete your cheapest shipping boxes request form below, so we can respond to your enquiry.

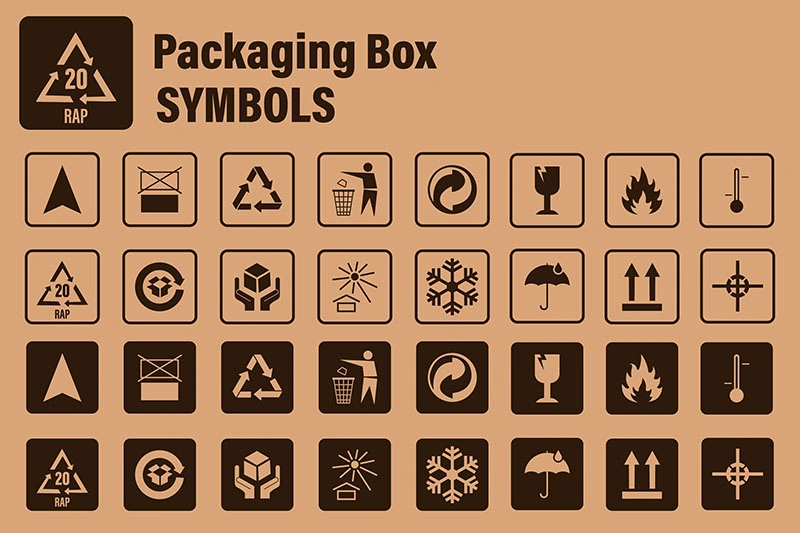

Beginner’s Guide to Shipping Boxes Symbols

Symbols aren’t just for aesthetics; they’re a universal visual language that directly informs customs, logistics companies, and end consumers on how to handle your product. Incorrect or missing symbols can lead to delays, fines, and even product returns. Click to study furhter.