Printed mailer boxes factory

- Custom Logo and Size: We design mailer boxes to perfectly match your product’s exact size and style.

- MOQ 100: XiangGe offers both digital and printed mailer boxes, allowing you to experiment with new packaging solutions without the pressure.

- Full-Color Printing: We support CMYK and Pantone color printing for vibrant colors without color shift.

- Professional 3D Design Tools: Free 3D preview makes design a breeze.

- Recyclable: Made with FSC-certified environmentally friendly materials.

What are mailer boxes

The mailer boxes, also known as airplane boxes or die-cut boxes, are cardboard packaging pre-stamped with creases and gussets through a die-cutting process. Their unique design features a one-piece construction, eliminating the need for tape closures. Their ingenious tongue and latch design makes them easy to fold and close. They are durable and can be customized in terms of size, cover material, corrugation type, and even printing and inserts. Learn mailer box material affects their durability information.

What are the benefits of printed mailer boxes?

Eco friendly. Kraft mailer boxes are fully recyclable and naturally biodegradable. They compost completely within weeks without harming the environment.

Superior Protection. The mailing paper has high elasticity and exceptional tear resistance. The strong construction effectively protects contents during shipping.

Food-Safe Options. Food-grade kraft paper is safe for direct food contact. The gift boxes are perfect for delivery and food packaging. They offer oil-resistant, water-resistant, and moisture-proof properties.

Smart Design Features. Mailing package boxes have excellent breathability that prevents moisture buildup. The durable construction resists damage during handling.

The Complete Package. The shipping boxes deliver environmental responsibility, product protection, food safety, and cost efficiency. They are the smart choice for businesses prioritizing sustainability and performance.

Custom mailer boxes wholesale

Browse the mailer boxes we crafted for customers from all walks of life below, from simple style to luxurious and exquisite, from environmentally friendly and practical to creative, each design carries a unique story of the brand. Here, I hope you can find your own packaging design inspiration.

Custom design mailer boxes

Custom made mailer boxes can be designed with paperboard materials, flute type, surface add-ons, printing sides, and sizes in mind. We can also provide free design advice.

- Paperboard Materials

- Fluting Type

- Surface Finishing

- Printing sides

- Size

Paperboard Materials

The face paper is the paper on the surface of the mailbox cardboard, which directly affects the appearance and printing effect. Common face papers include kraft paper, natural kraft paper, white kraft paper, white face paper, and coated white cardboard.

Kraft Linerboard

Made from kraft softwood pulp, it is the strongest type of paperboard. It has good tear resistance, burst resistance and folding resistance.

Natural Kraft

It presents a classic untreated natural brown color with a slightly rough fiber texture on the surface. It retains the strength of wood fiber, has excellent toughness and strong impact resistance.

White Kraft

The surface of kraft paper is bleached to present a cleaner white color. It still retains some of the fiber texture of kraft paper, but is smoother than natural kraft paper.

Coated Kraft Liner

One side is white coating layer, the other side is kraft paper. The white side has excellent printing effect and good gloss, which is a common choice for mailing boxes.

Coat White Paper

It has a smooth surface, excellent printability, and high color reproduction, and is often used in packaging that requires high printing aesthetics.

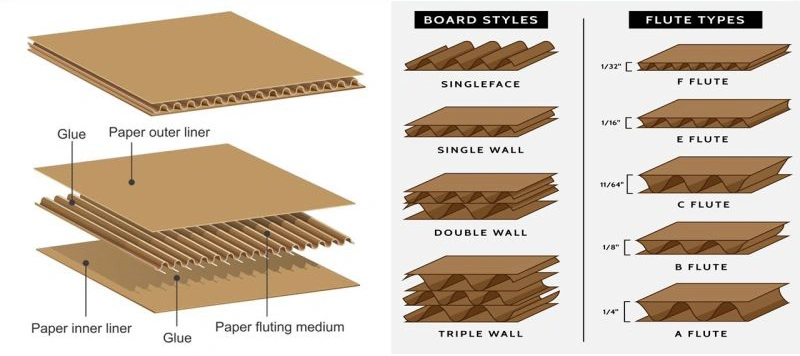

Fluting Type

Corrugated paper is a wavy paper layered between the face and backing paper, providing cushioning, protection, and support. Based on the number of layers, it can be categorized as single-faced, three-layer, five-layer, or seven-layer.

Based on the specific fluting type, corrugated paper can be classified as A-flute, B-flute, C-flute, E-flute, and F-flute. You can choose the most suitable corrugation type for your mailbox based on its load-bearing capacity and printing requirements. You can also choose a combination of corrugations, such as EB flute (E-flute on the front and B-flute on the back), which combines the printability of E-flute with the high strength of B-flute. Learn more about corrugated boxes.

Surface Finishing

Post-printing surface treatment can enhance the visual effect, improve the packaging brand image and provide additional protection. Common surface treatment processes include lamination, glossy film, matte film, touch film, UV varnishing, full UV, partial UV, hot stamping, hot stamping, embossing/debossing and embossing. Each process has its own unique effect.

Find out details.

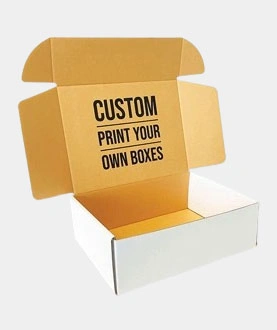

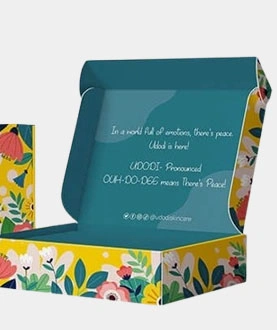

Printing Sides

You can choose which side of the box to print on to showcase your brand and packaging information. Common printing options include outside printing, inside printing, full printing, and no printing.

Outside Print Only

The most common choice, the brand message and design are displayed on the outside of the box.

Inside Print Only

Keep the exterior plain or monochrome, and print a pattern or brand story on the interior.

Both Inside Print

Provide the most comprehensive brand display space, echoing inside and outside.

No Print & Plain

Only packaging function is required, no brand printing is required.

Custom in Size

To ensure your products fit smoothly and are well protected, all of our customizations are based on interior dimensions. You will need to measure the interior length, interior width, and interior height. We will factor in buffer space if necessary. No matter how unique your product dimensions are, we can customize mailer boxes with logo to perfectly fit your L x W x H dimensions.

Custom mailer boxes template today

Fill in your basic information to custom mailer boxes packaging, and our team will contact and design within 1 day.

Why choose us as mailer boxes supplier?

We are the mailer boxes manufacturer in China. You can save the middleman and enjoy the most competitive price directly, which can really help you save your budget.

We have a strict quality control system and have passed ISO9001 certification. From the inspection of carton raw materials to the control of production process, to the final inspection of finished products, we strictly control every link to ensure that every batch of printed mailing boxes delivered to you maintains consistent quality.

We have rich export experience and have successfully exported cartons to more than 50 countries and regions around the world. Whether it is customs declaration, customs clearance or international logistics transportation, we have rich experience to ensure that your goods are delivered on time, so that you can worry-free throughout the process.

We provide flexible minimum order quantity. Whether you are a new brand that is just starting out and needs a small trial order, or a large customer with stable sales, we will fully cooperate to meet your business needs at different stages.

We promise 24*7 fast response and efficient production capacity. After the order is confirmed, we will quickly arrange production and strictly control the production cycle to ensure that your project can proceed on time without delaying your market plan.

How to work with us

XiangGe is your reliable mailer boxes manufacturer. We have a trusted supply network as well as we offer the latest production and design ability. Here are the reasons why you should choose us customize mailer boxes.

Evaluation

Tell us your basic needs, the approximate size of the paper boxes you want to make, the estimated quantity, and whether you have a vague preliminary design idea or sample.

Quotation

We will provide you with a detailed quotation soon. At the same time, if necessary, we will provide professional mailer boxes packaging die-cutting files for your confirm.

Design

We recommend that you make a sample confirmation. In this way, you can touch the material with your own hands and see the actual printing effect to avoid deviations before mass production.

Mass Production

We will produce each batch of customized print mail boxes in strict accordance with the specifications and requirements.

Inspection

We will conduct strict quality inspection to ensure that each mailbox meets the standards. We will pack and arrange transportation delivery for you.

Why are our clients saying

Since working with XiangGe, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The priority mailer boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of printed mailer boxes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete your mailer boxes with log request form below, so we can respond to you.