Mail letter envelope factory

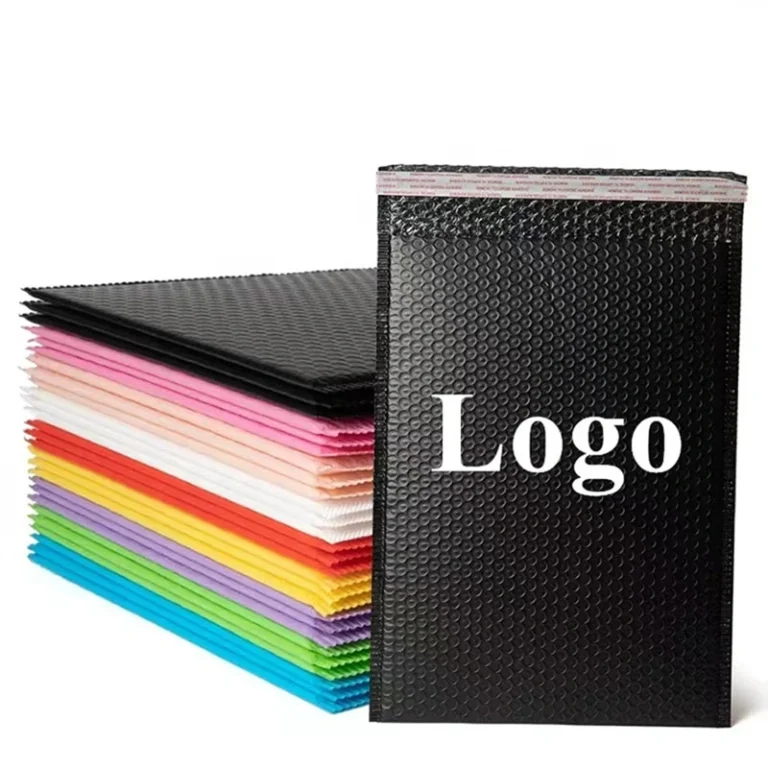

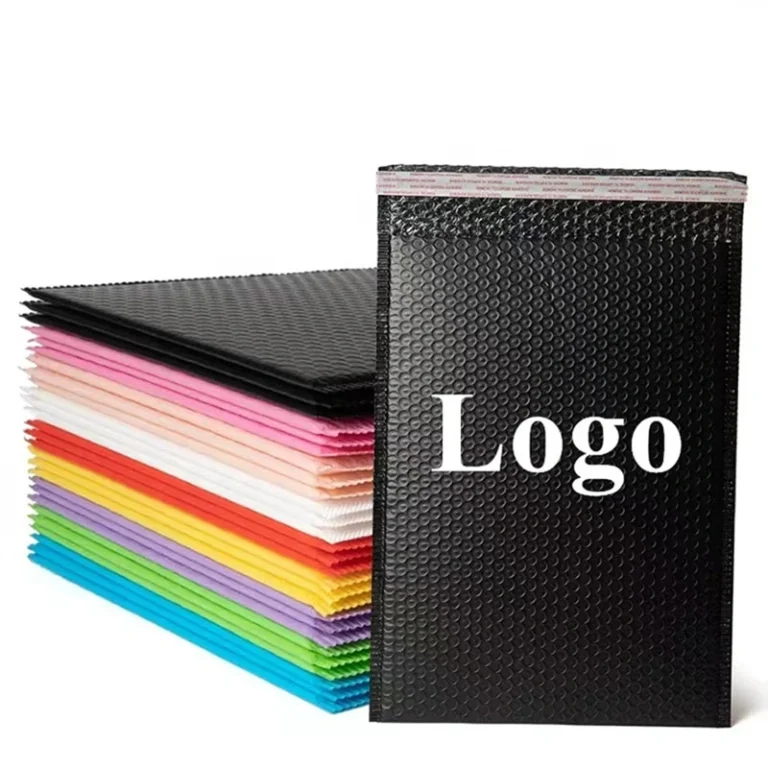

Bubble envelopes contain bubble film and are self-sealing, eliminating the need for additional tape. They can be printed with your logo and text, protecting your products from damage or scratches during transport. They offer better protection than standard envelopes and withstand normal drops, throws, and handling. They are ideal for packaging flat items. Contact us to get your latest envelope packaging.

- Customized envelopes make your business appear reliable and trustworthy. Your branding creates a strong first impression before your customers even open the envelope.

- Bubble envelopes are commonly used to package jewelry and accessories, documents, CDs and DVDs, small electronics, and educational materials.

- Customized envelopes demonstrate your attention to detail. Your customers can be confident in your products.

What are letter & bubble envelopes

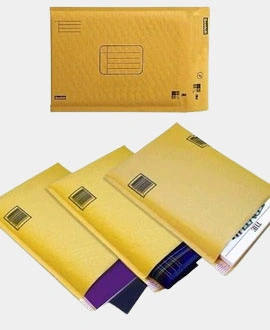

Letter envelopes are simple flat paper containers for documents and mail. They’re made from regular paper or cardboard and come in standard business sizes. You can print your company logo, address, and colors directly on them. They work great for invoices, contracts, marketing letters, and official documents.

Bubble envelopes are padded mailers with protective air cushions inside. The outside looks like a regular envelope, but the inside has small air bubbles that protect fragile items during shipping. They’re perfect for jewelry, electronics, cosmetics, small parts, and anything that could break or get damaged. The bubble lining keeps products safe while still looking professional on the outside.

Both types can be customized with your branding and come in different sizes. Letter envelopes range from small business card size to large document size. Bubble envelopes go from tiny jewelry pouches to big book-sized mailers.

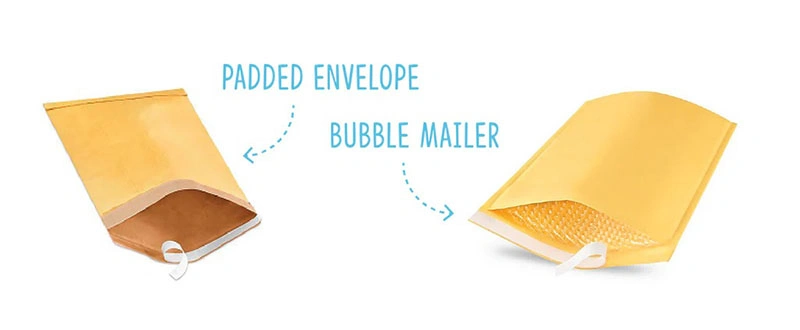

Bubble mailers use air-filled plastic bubbles for protection. You can see and feel the individual bubbles inside. Padded mailers use other materials like foam, fabric, or recycled paper stuffing. The padding feels softer and more uniform.

Protection Level: Bubble mailers give good protection for lightweight fragile items like jewelry or phone cases. Padded mailers offer better cushioning for heavier or more delicate items. The foam or fabric padding absorbs impact better than air bubbles.

Cost Difference: Bubble mailers cost less to make and buy. The bubble wrap inside is cheap and easy to produce. Padded mailers cost more because foam and fabric materials are more expensive.

Environmental Impact: Padded mailers are often more eco-friendly. Many use recycled materials or biodegradable foam. Bubble mailers use plastic bubbles that don’t break down naturally. However, both can be reused multiple times.

Appearance: Both look similar from the outside. The main difference is what you feel when you squeeze them. Bubble mailers feel bumpy with air pockets. Padded mailers feel smooth and squishy.

Best Uses: Use bubble mailers for light items that need basic protection. Use padded mailers for valuable or heavy items that need extra cushioning. Electronics, glassware, and expensive jewelry work better with padded mailers.

What is the difference between padded and bubble envelopes?

Wholesale letter & bubble envelopes

We offer a wide selection of dimensions, colors and craftsmanship, allowing you to carefully select every detail of your envelope. Browse these envelope and bubble envelopes we design and produce below.

Custom printed letter & bubble envelopes

- Printing

- Color Choice

- Printing Area

Printing

The main printing methods for envelopes and bubble mailers are as follows:

- Offset print

- Digital print

- Screen printing

- Flexographic printing

Screen Print

It can print metallic, fluorescent, luminous and other inks. It is suitable for high-end gift envelopes, VIP customer bags, and invitations for special occasions.

Offset Print

Best suited for bulk orders of 1,000+. Corporate envelopes, official document bags, large marketing event supplies.

Digital Print

No plate making is required, suitable for small batches of 100-1000 pieces. Startups choose digital printing for trial printing, personal customization, and urgent orders.

Color optional

- CMYK

- Single color

- Double colors

- Unique color

CMYK

We can print photos, complex patterns, and gradient colors.

Pantone Color

International standard color system, each color has a special number to ensure that there will be no color difference.

SIngle Color

Single-color printing has low cost and is suitable for orders with limited budget.

Printing area

The printed content should be coordinated with the overall proportion of the envelope, with appropriate blank space left to avoid printing in the barcode scanning area.

Front Print

The front is the best place to display the brand. The logo can be placed in the upper left corner where it is easy to notice.

Back Print

Print detailed contact information, such as full address, phone number, fax number, email address, website, etc. Don’t print too densely.

Front & Back Print

Make sure your branding is visible from any angle. Emphasize the logo and brand name on the front, and add more details on the back.

The right side shows our bubble envelopes custom process. Upload your design and we will provide the design online for free.

How to custom letter & bubble envelopes

Step 1: Share your logo and design files to our team. We accept PDF, AI, CDR formats. If you don’t have a design, our in-house design team can create one for free. Just send us your company information and tell us what you want.

Step 2: Choose your specifications. We’ll help you pick the right paper type, size, and colors. Our most popular options are kraft paper envelopes in standard business sizes. We have white, brown, and colored paper in stock at our factory.

Step 3: Get free quote and design. We’ll send you a detailed quote including unit price, setup fees, and shipping costs to your country. Our MOQ is 500 pieces for custom printing.

Step 4: Approve the sample. We’ll make a physical sample of your envelope and send photos for approval. If you want to see the actual sample, we will arrange TNT, DHL or other express delivery. It takes 3-5 days international delivery.

Step 5: Production Starts. Our factory begins production after receiving your deposit. Standard production time is 3~5 working days for real orders.

Step 6: QC inspect. Our QC team inspects every batch before packing. We check print quality, colors, cutting precision, and overall appearance. We follow the same quality standards we use for our carton box production.

How XiangGe Package produce letter & bubble envelopes

Below are our letter & bubble envelopes with logo manufacturing process:

Step 1: Paper Preparation. Start by cutting large paper rolls into sheets that match your envelope size. For letter envelopes, use regular paper or cardboard. For bubble envelopes, prepare both the outer paper layer and the inner bubble wrap material that will provide cushioning protection.

Step 2: Design Printing. Print customer logos and designs onto the paper sheets using offset or digital printing machines. Apply the correct colors and ensure all text is clear and properly positioned. Let the printed sheets dry completely before moving to the next manufacturing step.

Step 3: Cutting and Shaping. Use die-cutting machines to cut the printed sheets into the exact envelope shapes. Score fold lines where the envelope will bend and crease. Cut precise holes for handles if needed. Stack all cut pieces in proper order for assembly work.

Step 4: Assembly and Gluing. Fold the envelope pieces along the scored lines and apply strong adhesive to create seams. For bubble envelopes, attach the bubble wrap lining to the inside before sealing. Press all seams firmly and let glue cure for proper bonding strength.

The manufacturing process typically takes 5-7 days from raw materials to finished envelopes, depending on order complexity and quantity requirements.

Why choose us as letter envelopes manufacturers

Whether you are considering envelopes or bubble mailers, we at XiangGe can customize printed letter envelopes sample, which is a quick and affordable way to promote your brand. We can provide one-stop express packaging services.

Factory Prices

We’re the Ningbo packaging manufacturer. You get wholesale prices directly from our factory in China. No extra markups or hidden fees.

Fast Delivery

Our modern equipment produces your order in 3-5 days, not weeks. We have dedicated production lines for envelopes and bubble envelopes.

Quality Guarantee

Every envelope gets inspected before shipping. We use the same quality standards as our carton box production. Strong seams, clear printing, and proper sizing guaranteed.

Free Design

Our English-speaking design team creates your artwork at no extra cost. Just send us your logo and requirements. We’ll handle the rest.

Global Shipping Experience

We ship worldwide with reliable tracking and insurance. Sea freight, air freight, or express delivery options available.

What are our clients saying

Since working with XiangGe, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The bubble letter envelopes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of letter envelopes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete fold letter & bubble envelopes request form below, so we can respond to you within 1 day.