Kraft gift boxes factory

- Long fiber composition for max strength

- Good pressure resistance

- Ideal for high-end corrugated boxes

- 100% natural wood pulp materials

- Completely biodegradable

Renewable resource

Fiber material made from 100% recycled materials.

Recyclable

Most recycled cardboard boxes we produce are built for reuse, maximizing environmental benefits.

FSC Certification

FSC-certified recycled corrugated materials ensure responsible sourcing.

Made in China

Our mature supply chain infrastructure delivers consistent, reliable results.

Eco-friendly kraft boxes custom solution

Custom kraft paper boxes are a smart choice for e-commerce and restaurant takeout packaging. Sustainable packaging saves costs and resources, attracts environmentally conscious consumers, and increases your customer loyalty.

- Built-in dividers protect food and e-commerce items

- Foil stamping: Perfect for holiday gift boxes

- Demonstrate brand environmental commitment, align with market trends

- Customers can reuse boxes, extending your brand exposure

7 Types of Kraft Paper Boxes

Versatile kraft boxes packaging meets all your business needs. Below are 7 common kraft printer package boxes. Study what kraft papers are and why they are popular.

- Kraft Cardboard Boxes. Good for food, cosmetics, and electronics packaging.

- Kraft Gift Boxes. Perfect for small gifts with ribbon and decoration options.

- Kraft Paper Bags. Ideal for groceries, clothing, and accessories that replace plastic alternatives.

- Corrugated Kraft Boxes. Better for heavy-duty shipping and storage solutions.

- Kraft Bubble Mailers. Protective envelopes with bubble lining for small valuable items.

- Kraft Envelopes. for letters, invitations, and marketing materials with custom branding options.

- Kraft Product Sleeves. for CDs, DVDs, and small electronics with branded design capabilities.

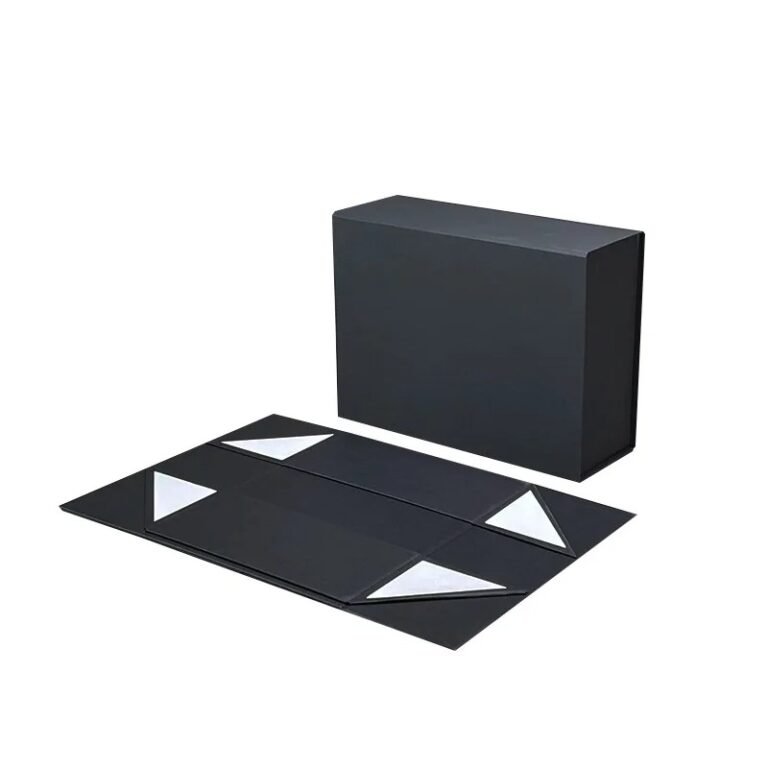

Wholesale gift kraft paper boxes

With over 10 years of experience in custom gift kraft boxes manufacturing and wholesale, we precision-cut every shipping box to your exact specifications for perfect product fit. Browse our popular styles below to find inspiration for your packaging needs.

Bulk kraft gift boxes design

Your kraft paper packaging boxes can be customized from the following aspects, paper materials, load ability, surface add-on, printing, until it meets your product and brand demands.

- Paper Materials

- Load Ability

- Finishing

- Printing

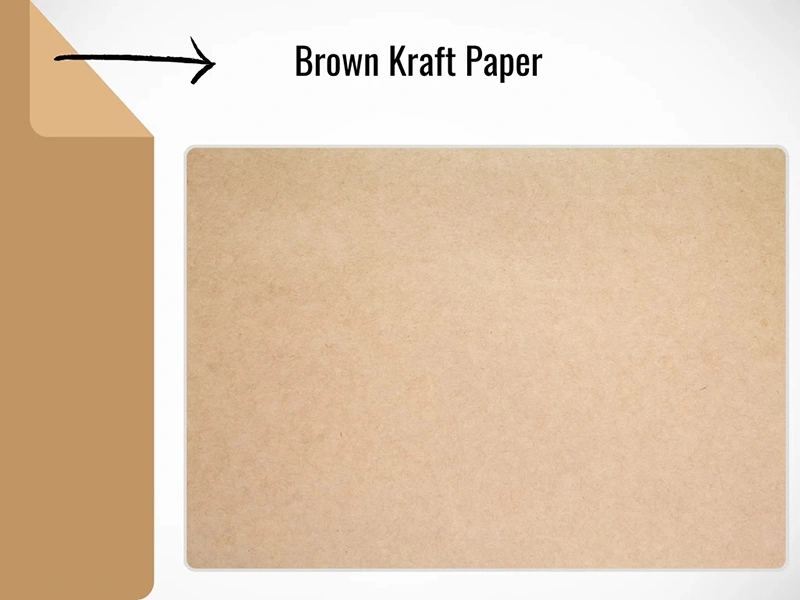

Kraft paper box material

- Natural brown color: comes directly from wood pulp fibers.

- Superior strength: Long, strong fibers provide exceptional durability.

- 100% Eco-Friendly: unbleached, chemical-free production.

- Learn more paper material options. →

Kraft Paper Load Capacity

Simple Rule: Thicker paper = stronger boxes. The load-bearing capacity increases directly with paper thickness and weight. Heavier kraft paper creates more rigid, durable boxes that can handle greater weight.

Easy thickness calculation: use this simple formula to estimate thickness: Thickness (mm) = Paper weight (g/m²) × 0.12

Example: 350g kraft paper = 350 × 0.12 = 42mm thickness (approx 0.42mm)

| Weight (g/m²) | Thickness | Best For | Load Capacity |

|---|---|---|---|

| 100g | 0.12mm | Light items | Up to 2kg |

| 150g | 0.17mm | Small products | 2-5kg |

| 230g | 0.27mm | Standard items | 5-10kg |

| 300g | 0.43mm | Heavy products | 10-20kg |

| 450g | 0.56mm | Extra heavy | 20kg+ |

- Light products → Use thinner, lighter kraft paper (cost-saving).

- Heavy products → Choose thicker, heavier kraft paper (max protection).

- Know your accurate weight to select the right paper strength.

Finishing

These professional surface treatments can be applied individually or combined to achieve your exact visual and functional requirements, creating packaging that perfectly represents your brand.

- Lamination

- Spot UV

- Embossing/Debossing

- Window Cutting

- Gluing

- Shrink Wrap

Lamination

Protective films for durability and appeal.

Spot UV

Selective coating for visual contrast.

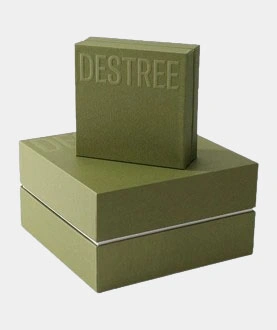

Embossing Debossing

Textured patterns for tactile experience.

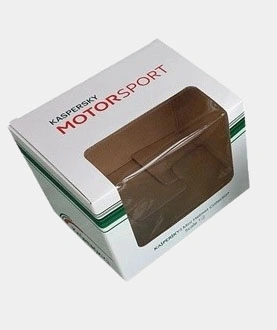

Window Cutting

Clear panels to display products.

Glue Sealing

Additional materials for strength.

Shrink wrap

Complete protection overlay.

Printing Options

Kraft box printing methods – quick selection compare and guide.

- Flexographic

- Offset

- Screen

- Digital

- Direct

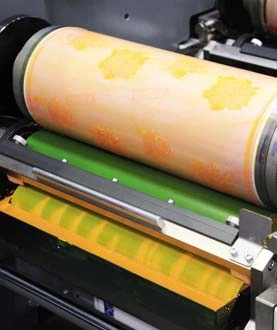

Flexographic

Best for: Large orders, simple designs

Advantages: Fast, cost-effective

Ideal use: Basic logos, single colors

Offset

Best for: Complex, high-quality designs

Advantages: Superior detail and color accuracy

Ideal use: Full-color artwork, photographs

Screen

Best for: Small runs, bold colors

Advantages: Vibrant, opaque inks

Ideal use: Simple designs with few colors

Digital

Best for: Small batches, custom designs

Advantages: No setup costs, quick turnaround

Ideal use: Personalized packaging, prototypes

Direct

Best for: Corrugated boxes, fast production

Advantages: Print directly on assembled boxes

Ideal use: Simple kraft and corrugated packaging

Get brown kraft paper boxes today

Fill in your basic information for gift kraft boxes, and our team will contact and design soon.

How to measure the kraft boxes dimension?

Here’s how to measure kraft paper boxes the right way — in simple steps:

1. Open the box flat

Make sure it’s fully opened and empty so you can measure the inside.

2. Measure the length (L)

This is the longest side at the base of the box.

3. Measure the width (W)

This is the shorter side at the base, right next to the length.

4. Measure the height (H)

This is from the bottom to the top of the box (how tall it stands).

5. Use the right order

Always write it in this order:

Length × Width × Height

Example: 10 × 7 × 4 inches

Here are the main things that decide the shade (light or dark) of kraft cardstock:

1. Type of pulp used

If it’s made from recycled paper, it’s usually darker. If it’s made from fresh wood pulp, it tends to be lighter and cleaner-looking.

2. Bleaching or not

Unbleached kraft is brown. Bleached kraft is lighter or even white. No bleach = more natural and darker color.

3. Wood type

Softwood (like pine) makes a different shade than hardwood (like oak). Different trees, different tones.

4. Additives or coatings

Sometimes, small amounts of clay or chemicals are added to change the shade or make it smoother. That can lighten or even out the color.

What factors determine the kraft cardstock shade?

How XiangGe Package produce kraft boxes

There are 7-Steps kraft box production process: Raw material preparation → design layout → printing → slitting and pressing line → die-cutting → forming and bonding → quality inspection and packaging.

Step 1: Large paper rolls are processed through corrugating, gluing, bonding, shaping, cutting, and creasing operations to create corrugated cardboard sheets meeting required specifications.

Step 2: Once the design is finalized (including size, graphics, and structure), we create printing plates and die-cutting tools to prepare for production processes.

Step 3: Graphics and text are printed onto the corrugated cardboard using flexographic printing technology, which delivers efficient multi-color printing results.

Step 4: Specialized machinery cuts the cardboard to predetermined widths and creates fold lines that enable proper box assembly.

Step 5: Precise cutting and creasing shapes the cardboard into flat box blanks ready for assembly.

Step 6: The flat blanks are folded into box shape and secured using adhesives or mechanical fasteners to ensure structural integrity.

Step 7: Final inspection verifies dimensions, print quality, and structural strength before packaging finished boxes for shipment.

Why choose XiangGe as kraft paper box manufacturer

Choosing us as your kraft paper boxes factory is a smart, dependable decision that delivers premium packaging boxes for your business.

Expertise

We focus exclusively on kraft paper and corrugated packaging solutions for catering, food delivery, cosmetics, and mailing applications.

Premium Materials

Our natural kraft paper boxes offers exceptional durability while recyclable. It provides reliable product protection during shipping and storage.

Advanced Manufacturing

We employ efficient, precision Heidelberger printing, die-cutting, and assembly processes that guarantee consistent quality and on-time delivery.

Customization

Whether you need sample prototypes or large-scale production runs, we deliver precisely packaging with design and accurate printing.

Social Responsibility

We use green, environmentally responsible materials that help establish your brand as an environmental leader.

What are our clients saying

Since XiangGe kraft paper boxes, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The kraft boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of your kraft package boxes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact us

We’d like to hear from you. Please complete your kraft shipping packaging box request form below, so we will respond to you.