If you still receive a deformed box or even a damaged product, you need to learn more about materials and replace it with the correct mailing box promptly to avoid further damage and financial losses. We can help you solve this problem.

This article will answer your questions:

- Common mailing box materials and their strength characteristics

- How flute type and thickness affect cabinet performance

- Which is more durable: kraft paper, white cardboard or coated board?

- How to use ECT and Mullen test materials

- Which material is best for export?

What are the common materials for mailing boxes?

- Kraft paper: Made of wood pulp as the main raw material, it has strong tensile strength and bursting resistance, good water resistance, and is suitable for heavy cargo and export transportation.

- White cardboard: Common weight is 210~300g, with smooth surface and good printing effect, but its strength is 10–15% lower than that of cowhide.

- Grey board/coated board: Good printing quality, high tear resistance and durability, but poor impact resistance, suitable for light goods display, not suitable for high stacking storage.

Professional Tips: If you need to mail heavy or moisture-proof products, it is recommended to choose kraft paper; if you need high-end and visually appealing packaging, white cardboard is recommended; if you need structural support or lining for the packaging, gray board is recommended.

Comparison of common mailing box materials

| Material Type | Strength Level | Print Quality | What It Means for You |

|---|---|---|---|

| Kraft Corrugated Board | High | Medium | Strong protection for exports and heavy shipments. |

| White Cardboard (SBS) | Medium | High | Great for premium retail appearance. |

| Coated Board | Low | Very High | Excellent display look, but weak for stacking. |

Practical advice

- Heavy cargo transportation: Choose kraft corrugated paper to ensure transportation safety and protect the product.

- Retail unboxing experience: White cardboard or coated board can provide good visual effects.

- Environmentally friendly: Recycled kraft paper with high ECT strength is also reliable.

Case: After a British cosmetics brand switched to kraft E-corrugated cardboard instead of white cardboard, the transportation damage rate dropped by 35%.

How do material thickness and flute type affect durability?

- E-flute (1.2–1.5mm): It has a smooth surface, good printing effect, and low cushioning capacity. It is suitable for small electronics, cosmetics, and inner boxes. It requires additional outer packaging before shipping.

- B flute (2.5–3mm): It has good strength and printing effect, and is suitable for transporting medium-weight goods.

- Double-walled BC/EB fluting (5–6 mm): Optimal compression resistance and cushioning, suitable for export and fragile, high-value goods.

| Flute Type | Thickness | Cushioning | Suitable Applications |

|---|---|---|---|

| E Flute | 1.2–1.5mm | Low | Light goods, retail displays |

| B Flute | 2.5–3mm | Medium | General e-commerce shipping |

| BC Flute | 5–6mm | High | Heavy exports / fragile items |

Professional Tip: Triple-layer double-corrugated with kraft face paper can increase ECT by more than 50% compared to single-layer.

Study further comprehensive guide to packaging materials information here.

Which one is more durable: kraft paper, white cardboard, or coated board?

- Kraft paper: has a rough surface and is the first choice for export and long-distance transportation.

- White cardstock: Smooth and attractive, suitable for retail products.

- Coated board: smooth and delicate, good visual effect, strongest durability and good moisture resistance.

Therefore, coated paper is more durable than kraft paper, which in turn is better than white cardboard. If you want to balance appearance and strength, you can use a composite board with kraft core + white paper.

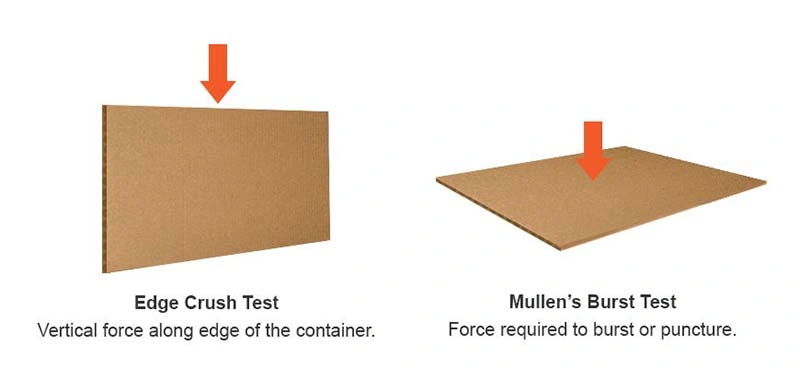

How can the ECT and Mullen test help you choose mailer boxes?

- ECT (Edge Compression Test): Measures the stacking capacity of the edge of the corrugated cardboard, that is, its stacking resistance.

- Mullen Test: Measures the surface puncture and burst resistance of corrugated cardboard. A higher value indicates better burst resistance.

- Domestic transport: ≥ Light or standard cargo transport, generally using 32 ECT.

- Export or fragile products: 44–48 ECT is recommended

As a carton factory, we are most afraid that customers do not have clear ECT or Bursting requirements, which will affect the subsequent acceptance and we cannot make judgments based on our feelings.

Which materials are best suited for export?

- Double-layer BC corrugated + kraft paper: The structure is stronger, can withstand greater external pressure, and has better moisture resistance.

- High humidity environment: requires moisture-proof glue corrugated core paper.

- Cold chain/wet cargo: PE coated kraft paper or wax treated kraft paper.

How do temperature changes affect material strength?

- High humidity: The material is easily affected by moisture, which will reduce the adhesive performance and the compressive strength by up to 30%.

- High temperature: High temperature will intensify the molecular movement of the packaging material and reduce the bonding strength of the glue on the coated cardboard.

- Ultraviolet rays: Accelerate fiber decomposition, destroy the molecular structure of the packaging film, and reduce the barrier performance of the packaging..

Can environmentally friendly materials provide strong protection?

How do materials affect compression and stacking performance?

- Material thickness and number of layers, such as single corrugated, double corrugated, and triple corrugated, have completely different effects.

- The combination of structural design and inner support, auxiliary materials such as sponge or insert can significantly improve the overall performance.

Which mailer box material is best for you?

| Product Type | Recommended Material | Reason |

|---|---|---|

| Lightweight Retail Products | White Cardboard E Flute + UV Coating | Premium look, suitable for display |

| Medium E-commerce Goods | Kraft B Flute + Water-based Coating | Balance of strength and print quality |

| Heavy or Fragile Items | Double Wall BC Flute + Kraft Liner | Maximum compression resistance |

| Cold Chain / Wet Goods | PE Laminated Kraft Paper | Moisture-proof and waterproof |

The most commonly used and cost-effective material for daily mailing is corrugated cardboard boxes. If you have special requirements for moisture-proof and waterproof materials, you can consider plastic mailing boxes.

Mailer box material trends 2025

The composite board of kraft core + white paper is becoming more and more popular. It takes into account the strength and support of the inner core and also meets the requirements of personalized printing on the surface.

Water-based coating replaces PE film, is environmentally friendly and recyclable, and can effectively isolate the penetration of moisture, air, etc.

FAQs

Yes, Kraft paper has longer fibers and is more durable (stronger, more tear-resistant, and more fold-resistant) than white cardboard.

BC flute (five-layer double corrugated cardboard) is the most common corrugated carton used in export transportation. It takes into account protection, cost and strength.

Yes, the shipping environment is complex, which requires ECT to meet the standards and to be moisture-proof and salt-resistant.

Conclusion

Durability depends on the combination of material, design, flute type and coating. For most export e-commerce companies, double-layer corrugated cowhide is the safest choice.

Next steps:

- Specify product size, weight, and fragility.

- Ask the carton manufacturer for ECT and Mullen test data.

- Test samples under real shipping conditions.

About XiangGe Package

We specialize in designing and producing high-performance mailing boxes for global brands. With over 10 years of export experience, we can match the optimal materials and fluting profiles for every shipping need. Our solutions balance protection, branding, and the environment.

Contact us: Get a free sample or inquire about a custom solution.

Internal links: