Folding paper boxes factory

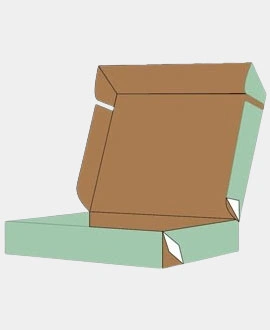

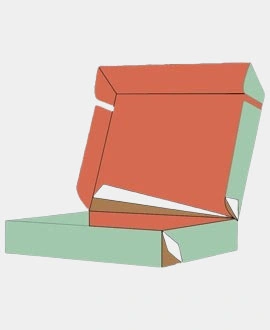

The folding box is the most space-saving and easy-to-assemble printed packaging. We customize and manufacture tuck boxes so they can be shipped flat, saving space and reducing shipping costs. Upon delivery, your shoes, food, medicine, cosmetics, and other products can be assembled in just 30 seconds. Give your packaging a fresh, new look with our foldable boxes.

- Custom folding box can be shipped and stored flat, saving 85% of storage space and being 2-3 times lighter than plastic boxes.

- Foldable packaging acts like a mini billboard for your business. You can print your logo and branding to enhance the impression it makes on your customers.

- No glue or tape is required for assembly, and the environmentally friendly PSC material allows your customers to easily recycle it without any environmental impact.

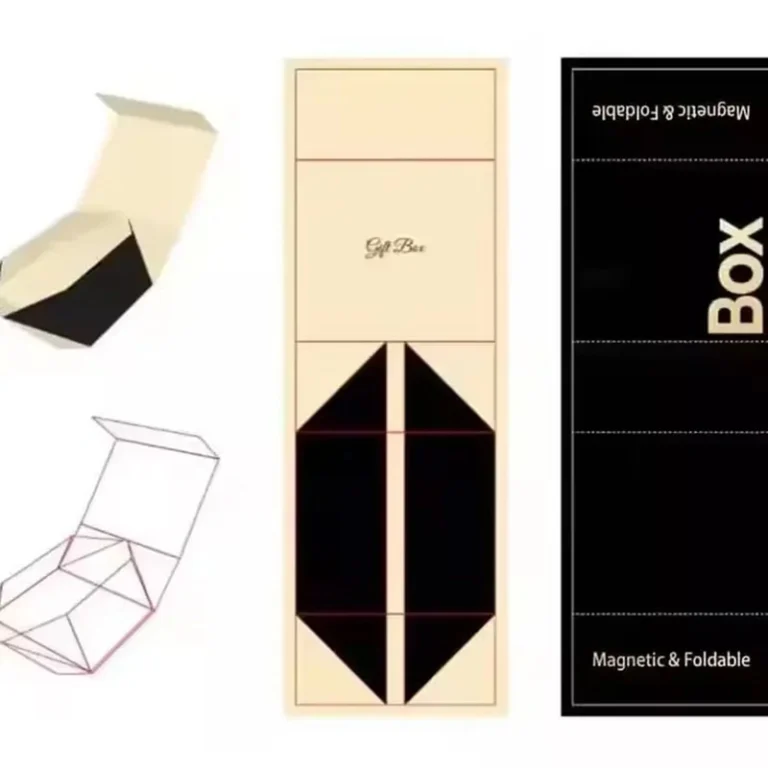

What are collapsible boxes

Collapsible boxes are boxes that you can fold flat when not in use. They are made from materials like cardboard, paper, or fabric. The reverse tuck boxes have foldable sides or panels that let you collapse the box into a smaller size. When you need them again, you can open them back up to full size. Many people use collapsible boxes for storage, moving, or shipping.

You’ll benefit from them:

- Save space when not in use

- Easy to store and carry

- Quick to set up and fold down

- Good for shipping because they take less room

- Reusable, so they save money and reduce waste

Custom folding boxes

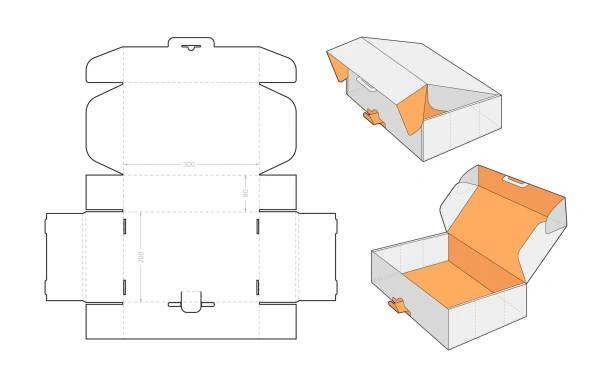

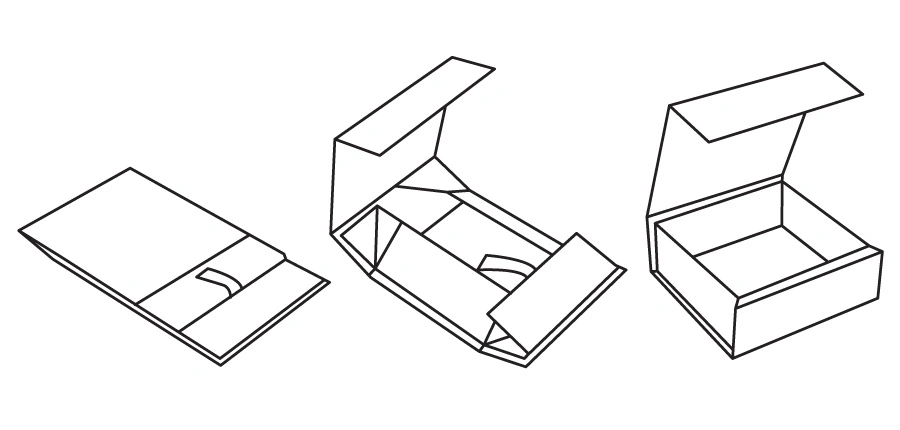

There are a few common folding box styles you can choose from, each with a different shape and closing method.

Straight Tuck End (STE): The top and bottom flaps tuck into the box from the same direction. Neat and clean look. It looks clean on the shelf, great for display products.

Reverse Tuck End (RTE): Top flap tucks in from one side, and the bottom flap from the opposite side. Easy to open and close. Quick to assemble, saves time.

Tuck Top Auto Bottom: Top tucks in like usual, but the bottom has a strong base that pops into place. No glue needed. Strong base, good for heavier items.

Seal End: Both ends are sealed with glue or tape. Great for heavier items or retail packaging. Secure packaging, ideal for shipping.

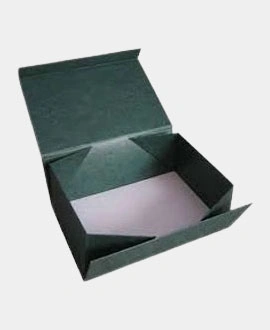

Sleeve Box: A box with no top or bottom—just a sleeve that slides over an inner tray. Often used for luxury packaging. Stylish and high-end look, great for gift boxes.

Tuck top boxes wholesale

We have over 10 years of experience in customizing and producing folding box, primarily for packaging perfumes, candles, and beauty products. Take a look at some of our current folding cartons to get inspiration for your own unique design.

Custom tuck end boxes

- Cardboard Weight

- Paperboard types

- Printing

- Surface add-on

Cardboard weight

Common cardboard weights for paper folding cartons range from 200 to 500 g/m².

- 200-250 gsm for lightweight packaging

- 250-350 gsm for regular product package

- 350-500 gsm for heavy duty or premium package

Lightweight

It is suitable for a wide range of applications in the packaging of daily consumer goods.

Regular

It is the most widely used packaging paper weight range on the market.

Heavy

It is ideal for packaging high-end, heavy-duty and high-protection product packaging.

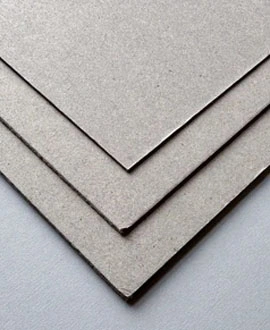

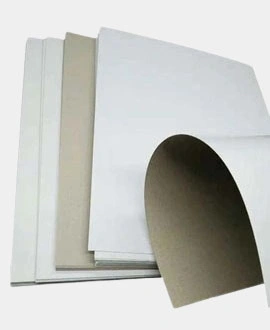

Paperboard types

The following paperboard types are widely used in folding box packaging design according to different product protection, printing and cost.

- Folding Boxboard (FBB)

- Solid Bleached Board (SBB/SBS)

- White Lined Chipboard (WLC)

- Greyboard

- Coated paper

Greyboard

Multi-layer waste pulp or thick paper, heavy and stiff.

Coated paperboard

Enhance wear resistance, moisture resistance and aesthetics.

White Lined (WLC)

Gray-brown core layer, low cost and environmentally friendly.

SBB SBS

Pure white, surface coating, excellent printing performance.

FBB

The inner layer is cream yellow, high stiffness and good printing performance.

Printing

We can print in full color on our high-end offset presses, and you can choose to print externally, internally, or both.

External print

Printing of patterns, company names, logos, etc.

Internal print

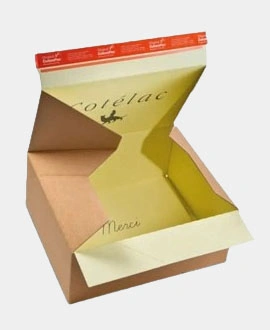

Deliver a brand story, product description or decorative graphics inside the folding box.

Fully print

Different contents can be designed on the inside and outside respectively, the outside is used to attract consumers, and the inside is used to enhance the brand story.

Add-on

Common surface treatment processes for folding boxes include UV coating, matte film and glossy film.

Know further surface treatment artworks.

Spot UV

It can be fully coated or partially UV-coated to enhance the visual and tactile effects.

Matte

The surface of the carton is covered with a matte plastic film to create a matte, non-reflective texture.

Glossy

The surface of the carton is covered with a smooth transparent plastic film, giving it a high-gloss finish.

Get folding box template today

Fill in your basic information for folding box carton, and our team will contact and design it within 24 hours.

The right side shows our folding box customization process. Upload your design and we will provide the design online for free.

How we custom folding box process flow

Step 1: Tell us what you need. Share your box size, quantity, box style, and how you want it to look.

Step 2: Choose materials and finish. We help you pick the right paperboard, coating, and special finishes like matte or gloss.

Step 3: Get a dieline template. We send you a layout file (dieline) to place your artwork correctly.

Step 4: Send back your design artwork. You apply your design to the dieline and send it back to us.

Step 5: Sample providing. We can make a printed sample so you can check everything before mass production.

Step 6: Final approval. You confirm the sample or final design so we can start production.

Step 7: Mass production. We print, cut, fold, and glue your boxes.

Step 8: Quality check and shipping. We inspect the boxes, pack them carefully, and ship them to you.

How XiangGe Package produce folding box

At XiangGe Package, we make high-quality collapsible boxes with care and precision. Here’s how we do it, step by step:

Step 1: Material Selection. We choose strong and smooth paperboard or cardboard, based on what the customer needs. You can pick the thickness, color, and surface finish.

Step 2: Cutting and Printing. We cut the material into flat sheets, then print your design using high-quality machines. We make sure the colors are sharp and clean.

Step 3: Lamination or Coating. We add a layer like matte, gloss, or soft-touch to protect the print and give it a nice feel.

Step 4: Die Cutting. We use a custom mold (die) to cut the box shape and folding lines, so the box can be folded easily and neatly.

Step 5: Gluing and Folding. We apply glue at the right spots and fold the box in a way that it can be flattened. This makes it easy to store and saves shipping space.

Step 6: Quality Check. Our team checks every batch to make sure the boxes look good and fold properly.

Step 7: Packing and Shipping. We pack the boxes flat to protect them during delivery, and send them to your door—fast and safe.

Why choose us as foldable box manufacturers

Entrust your rigid folding box and carton production to us at XiangGe and experience unparalleled reliability. With an excellent track record for over 10 years, we will provide expert support throughout the entire process.

Factory Direct

We are a factory based in China with 10-years of experience producing folding box. You get a good price and more control over your order.

Custom Solutions

Whether you need a small luxury gift box or a strong folding box, we can customize the size, shape, material, print, and finish to match your exact needs.

Premium materials

We use strong, eco-friendly paperboard, sharp printing, and clean folding lines. Every box goes through quality checks to make sure it folds well, looks great, and works as intended.

Reliable Production

Our skilled team and organized process let us produce orders quickly while keeping quality high. We also offer sample approval before mass production.

Friendly Support

We’re not just box makers—we’re your partners. Our team is here to answer your questions, help with design, and solve any issues fast.

What are our clients saying

Since working with XiangGe, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The moving folding box you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of card tuck box is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and XiangGe service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete your clear tuck top boxes request form below, so we can respond to you.