Coated paper suppliers

Coated paper offers a smooth surface and excellent printing quality, making it the top choice for high-end packaging. Common weights for coated paper include 200g, 250g, and 300g. Oiling or laminating can enhance its water and abrasion resistance. It’s commonly used in the cosmetics, electronics, luxury goods, food, and beverage industries, elevating your product’s quality and shaping your brand image. Contact us to discuss your coated paper packaging solution.

- Lightweight coated paper: 60, 70, 80g/m ².

- Standard coated paper: 100, 110, 128g/m ².

- Heavy duty coated paper: 157, 180, 200, 220, 250, 280, 300g/m ².

- Overweight coated paper: 330, 350, 400g/m ².

The advantages of high-quality coated paper

High-quality coated paper gives clear benefits that improve both print quality and business efficiency. Research in printing technology strongly supports these advantages.

- The paint is white, delicate and smooth, and the printed pattern is colorful with high restoration.

The fibers are evenly distributed, of consistent thickness, and have high elasticity and strength.

The layer effect is good, can meet the 60 lines/cm fine mesh printing, and is suitable for high-quality printing.

What are coated paper used for?

- Color printing: 100 ~ 130g coated paper is suitable for low-end promotional materials such as magazines, while 200g coated paper is suitable for high-end printing.

Packaging: Heavier coated paper is suitable for packaging materials such as packaging boxes, business cards, handbags, invitations, etc.

Advertising: used for exquisite printing of advertisements, posters, labels, trademarks, etc.

Wholesale coated paper boxes

XiangGe has been making paper products for the printing and packaging industry for over 10 years. We can create custom packaging in different sizes, shapes, and colors. Check out our recyclable coated paper boxes below for ideas and inspiration.

Custom coated paper box

- Types

- Functions

- Printing purpose

- Food packaging

Types of coated paper:

Coated Linerboard: face material for corrugated boxes and rigid fiberboard.

Coated Duplex Board: single-sided color printing applications.

Coated White Cardboard: premium packaging applications.

Coated Linerboard

Brightness ≥ 80-98%

Glossiness ≥ 40-70 Glossiness units

Printing surface roughness ≤ 3.5 μ m

Coated Duplex Board

Weight: 200-400 g/m ²

Thickness: above 0.1mm

SBS

C1S: Single powder card, coated on one side

C2S: Double powder card, double-sided coating

Coated paper function

Coated paper can be divided into the following 4 types according to their functions:

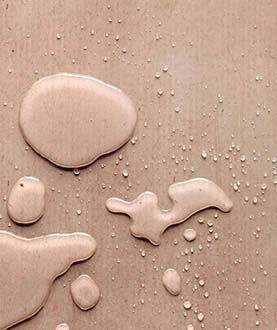

- Waterproof

- Oil

- PE

- Barrier

Waterproof

Up to the highest waterproof standard of R10.

Oil resistance

Prevent oil penetration and protect food and industrial products.

PE

Moisture proof, waterproof, oil proof, and have good air tightness.

Barrier

Block water vapor, oxygen, fragrance, etc

Printing purpose

Divided into 3 categories based on glossiness.

- Glossy

- Matte

- Semi-gloss

Glossy

High gloss, good mirror reflection effect

Matte

Matte, with a soft texture

Semi-gloss

Balancing visual effects and practicality between smooth and matte surfaces.

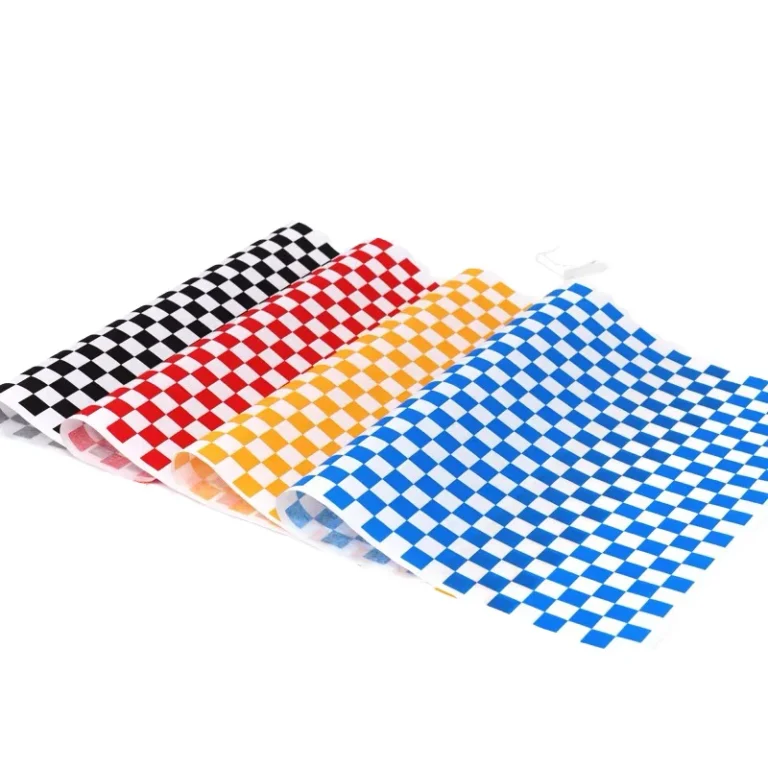

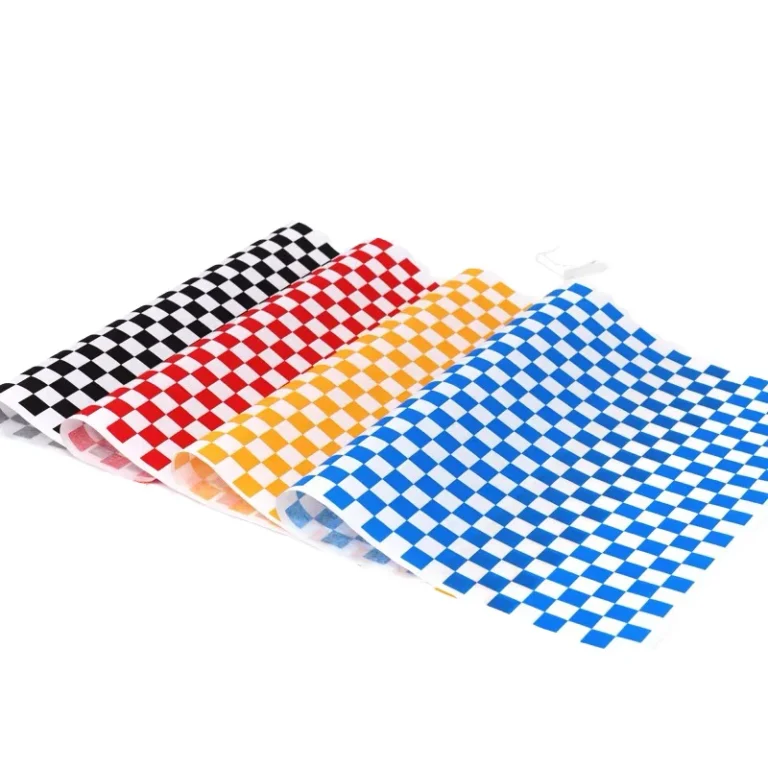

Food packaging coated paper

It can be roughly divided into three categories:

- Food grade

- Heat-resistant

- Frozen food

Food grade

The packaging that comes into direct contact with food complies with FDA and GB standards.

Heat-resistant

Can withstand high temperatures of 80-120 ℃, suitable for hot drinks and food.

Ice Cream Coated Paper

Maintain stable performance at -18 ℃ to prevent the influence of condensation water.

Get coated paper box mockup today

Fill in your basic information for coated paper plates bulk, and our team will contact and design for you.

What is the difference between coated and uncoated paper?

- Coated paper has an extra layer of coating than ordinary cardboard, making it easier to print with clear details, and is often used for high-end printed products.

Plain paper with a rough, matte surface, suitable for general printing: books and newspapers.

Coated paper has glossy and matte surfaces; uncoated paperboard has a natural feel and fiber texture.

Summary: Coated paper printing is beautiful, while uncoated paper printing is economical.

What are disadvantages of coated paper

The disadvantages of coated paper are also significant, mainly as follows:

- Poor folding performance: After your customers use it for a long time, the folding parts are prone to cracking, affecting the appearance.

- The stiffness is not high and it is easy to deform, so it is not suitable for rigid packaging boxes.

- Poor temperature resistance: high temperature and high humidity can easily cause it to fade or fall off.

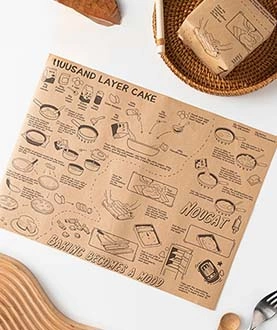

How XiangGe Package produce coated paper boxes

Below are our box package manufacturing process:

- Material preparation: We use coated paper for the surface and corrugated paper for the inner layer.

- Printing: We choose the right printing method based on the design and requirements. We add anti-offset powder to prevent ink from sticking.

- Surface treatment: If needed, we add film coating, wax coating, calendering, embossing, or hot stamping to improve the appearance.

- Die cutting and creasing: We make cutting plates based on the box design. Then we cut and crease the paper to create fold lines and slots for easy assembly.

Assembly: We use the fold lines to shape the box through gluing, stapling, or stitching.

Quality check and packaging: We inspect the finished boxes for size, print quality, and strength. Then we arrange shipping by sea or express delivery.

Why choose us as coated paper manufacturer

Choosing us for your copper plate paper and cardboard boxes will make your product packaging look better and help you stand out in the market.

High quality

Your coated paper boxes deliver excellent print quality and visual appeal, boosting your product packaging and brand image.

Edge tech

Our coated paper uses high-quality coating technology for a smooth, fine surface that creates bright, clear printing and enhances packaging appearance.

Customization

We offer custom printing, surface treatments, and box designs to meet both functional and visual needs for different products.

Durable

By combining coated paper’s excellent printing with corrugated paper’s strength, our boxes provide good resistance and protection.

Fully solution

We provide complete packaging solutions from material selection and design to production and quality control, with delivery in 3-5 days.

What are our clients saying

Since working with XiangGe, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The coated paper boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of XiangGe packaging boxes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete your coated packaging box request form below, so we will respond to you.