Cardboard packing boxes factory

- Recyclable: Fibers are made from 100% recyclable materials.

- FSC Certification: We can provide you with corresponding environmental reports.

- No plastic: The materials used to make the box are all natural fiber materials.

- Made in China: Xiangge provides professional services throughout the entire process.

Custom size cardboard boxes

Cardboard packaging box features

Excellent protection. It has a smooth and flat surface, suitable for high-quality printing, provides reliable product protection, and reduces damage and return rates.

- Cost effective. Lightweight design reduces transportation costs and ensures convenience in transportation and storage.

- Sustainable brand image. It can attract environmentally conscious customers and enhance your brand reputation.

- Completely customized. Tailor made sizes, printing, lamination, foil stamping, coating, handles, and windows to create unique packaging that sets your brand apart.

- Multi functional applications. Suitable for electronic products, food, gifts, and e-commerce – one packaging solution can meet all your product lines and reduce inventory.

Bulk large & small cardboard boxes

We produce cardboard boxes in various shapes (flat, heart-shaped, square, circular), ranging from mini to oversized sizes, as well as different colors. We provide complete customized design services to create what you want. Our cardboard boxes are made of high-quality kraft paper and use Heidelberg printing machines to ensure professional results every time. Browse through our typical corrugated cardboard boxes below.

Large cardboard boxes

perfect for moving, storing or shipping lightweight and household items.

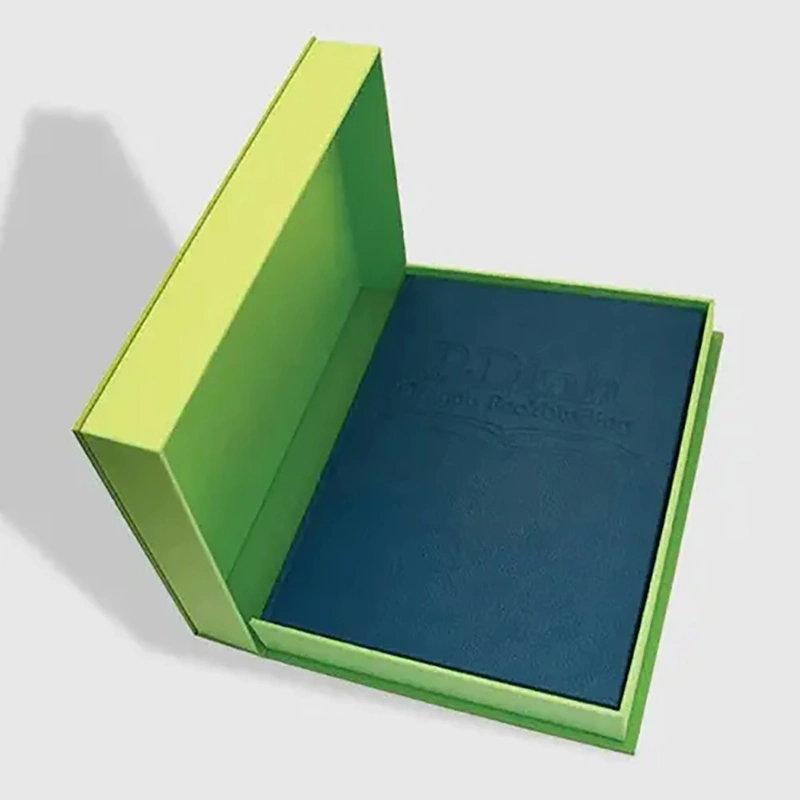

Custom cardboard box with lid optional

The options for customizing cardboard gift boxes include materials, sizes, phisical performance,inserts & partitions。 Get the best printed cardboard boxes for you.

- Dimensions

- Materials

- Physical Performance

- Inserts & Partitions

Cardboard box dimensions

We measure both inner dimensions (product space) and outer dimensions (shipping space) to ensure perfect fit for your products and shipping requirements.

Size Accuracy:

- Single wall boxes: ±3mm precision

- Double wall boxes: ±5mm precision

Paperboard Materials

Different types of ribs have different rib heights and buffering capabilities.

- A fluting: 4.5-5.0 mm

- B fluting: 2.2-3.1 mm

- C fluting: 3.1-4.0 mm

- E fluting: 1.1-2.0 mm

- F fluting: 0.6~0.75mm

Physical Performance

GB/T 13024-2016 Standards we met

- Superior durability and strength

- Crush-resistant edges

- Flexible without breaking

- Heavy-duty load capacity

Your will benefit: Reliable protection, fewer damaged products, consistent quality. Study further corrugated box standard requirements.

| Indicator | Premium Grade Standard | Qualified Grade Standard | Unit |

|---|---|---|---|

| Burst Index | ≥3.3 | ≥1.7 | kPa·m²/g |

| Edge Crush Strength (Ring Crush Index) | ≥9.5 | ≥5.7 | N·m/g |

| Folding Endurance | ≥60 | ≥35 | times |

| Compression Strength (Box) | ≥2000 | ≥4500 N/m (board edge crush strength) | Newton (N) |

Inserts & partitions

Dividers. Create separate compartments to prevent products from bumping into each other, thus protecting them from scratches and damage during shipping.

Soft Padding. Absorbs shock and vibration, protecting fragile items from impact damage.

Die-Cut Components. Custom-shaped cardboard components, including slots, tabs, and support frames, strengthen the box structure and secure products in place.

Get cardboard box design today

Fill in your basic information for luxury packaging boxes, and our team will contact and design it.

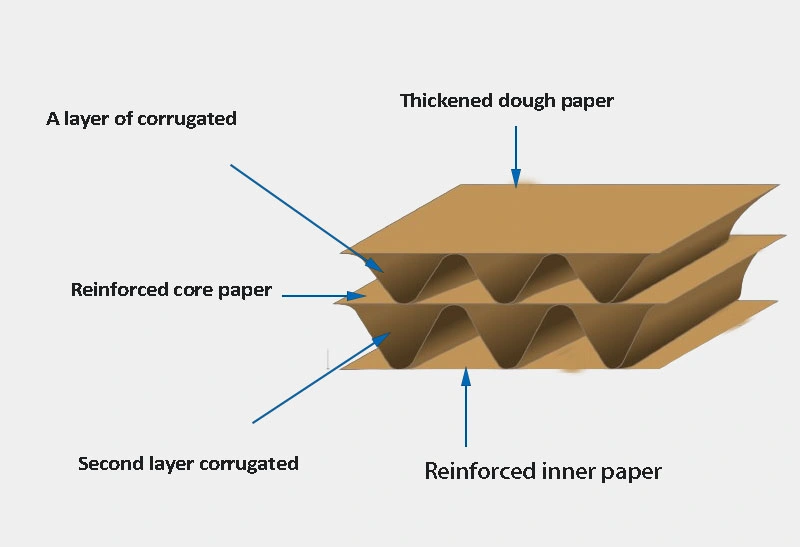

Structure of cardboard box for shipping

On the left is a typical internal structure diagram of a 2-sided cardboard box.

- Thickened face paper: isolates water molecules, prevents moisture, and does not deform.

- One layer of corrugated: Strong load-bearing capacity and good cushioning ability.

- Reinforced core paper: uniform stress and strong impact resistance.

- Second layer corrugated: shock-absorbing, drop resistant, and pressure resistant, sturdy and durable.

- Reinforced backing paper: resistant to impact and sharp objects.

How XiangGe Package produce cardboard boxes

Our Cardboard Box Production: 4 Simple Steps

Step 1: Board creation. We transform large paper rolls into strong corrugated board by creating the wavy middle layer and bonding it between flat sheets using eco-friendly glue.

Step 2: Cutting & shaping. The board is precisely cut to your box dimensions, with fold lines, flaps, and openings created exactly as needed for your design.

Step 3: Printing & design. Your logos, text, and graphics are printed using high-quality, environmentally-friendly inks that ensure sharp, professional results.

Step 4: Quality control & packaging. Every box is thoroughly inspected for accuracy and quality before being carefully packaged for shipment to you.

Why choose us as cardboard box manufacturer

Your trusted packaging maker here. XiangGe delivers premium cardboard boxes and creates eco-friendly, efficient, personalized packaging solutions that drive your business success.

Expertise

10 years specializing in corrugated packaging with 50+ skilled operators ensures consistent, high-quality boxes that protect your products and satisfy your customers every time.

Sustainable

Our eco-friendly materials and processes help you meet sustainability goals while appealing to eco conscious customers, strengthening your brand reputation.

Customize

Personalized packaging solutions not only protect your products but elevate your brand image, creating memorable unboxing experiences for you.

Quality Assurance

ISO-certified quality control guarantees perfect dimensions, strength, and printing in every batch, reducing returns and protecting your fame.

Quick Deliver

Streamlined production and logistics ensure 3-5 day delivery, help you meet launch dates and maintain customer satisfaction without delays.

What are our clients saying

Since cooperating with XiangGe, the breakage rate of our e-commerce products has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The cardboard boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of XiangGe Package is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete and get cheap cardboard boxes here, so we can respond to your enquiry.

Perfect Packaging Box Design: A Beginner’s Guide

You also want packaging that looks good, ships safely, and costs little. This guide explains product packaging design, from goals to testing. We offer some creative box designs, specifications, and practical rules for your reference, helping you overcome your challenges. Click here to study further information.