Carton dividers (also called partitions/inserts) don’t just keep products neatly organized. They also protect them, preventing them from being bumped and squeezed during transport. Whether you’re packing wine, perfume, or small electronics, choosing the right dividers can significantly reduce breakage. We produce over one million cartons with dividers annually. This article will help you choose the best divider type.

Last updated: August 2025 | Estimated reading time: 10 minutes

This article will answer your questions:

- Types and structures of common carton dividers

- How to choose the right divider for your product

- Design techniques to reduce breakage rates and improve the unboxing experience

- Common mistakes in using dividers

- Practical application cases in different industries

Why are cardboard box dividers so important?

The cardboard box dividers are layers placed inside packaging to separate individual products and protect them from damage during transport. Many products have various types of divider components built into them.

Falling, shaking, and stacking are common during transportation. The partition board can absorb external impact and ensure that the product will not shake or be damaged.

For example: When we receive mobile phones, laptops and other electronic products, they will have customized EVA sponges or inner trays to ensure that the devices are intact.

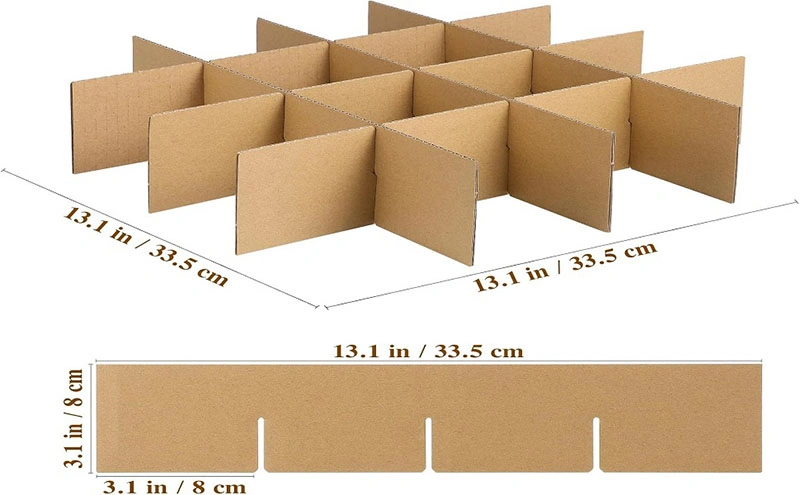

Common types of cardboard divider inserts

Classification by structure

| Material | Features | Recommended Use | Practical Benefit |

|---|---|---|---|

| Kraft Corrugated (E/B Flute) | Durable and recyclable | Standard dividers | High strength + eco-friendly |

| Greyboard | High density, rigid | Non-fragile items | Cost-effective |

| Honeycomb Board | Lightweight yet strong | Precision electronics | Shock absorption |

| PE-Coated Board | Moisture-resistant | Fresh food, cold chain | Prevents damp and softening |

| Black/Gold Card | Premium appearance | Gift boxes, cosmetics | Boosts visual appeal |

Tips: Only by selecting the product according to its type, fragility and mode of transportation (whether to stack boxes) can the product be truly protected.

Classification by material

| Material | Features | Recommended Application | Practical Benefit |

|---|---|---|---|

| Kraft Corrugated (E/B Flute) | Durable and recyclable | Standard divider inserts | High strength + eco-friendly |

| Greyboard | High density and rigidity | Non-fragile products | Cost-effective |

| Honeycomb Board | Lightweight yet strong | Precision electronics | Excellent shock resistance |

| PE-Coated Board | Moisture-resistant | Fresh food, cold chain | Prevents damp and softening |

| Black/Gold Card | Premium appearance | Gift boxes, cosmetics | Enhances visual appeal |

Practical suggestion: You can use thick cardboard for the outer box and thin gray board for the inner box partition, which saves money without reducing the protection ability.

Creative partition board design tips

Customize partition structures for specific products

Not all products are suitable for standard sockets. Here are some customization suggestions:

- Candlestick jar? Choosing a foldable corrugated sheath can effectively wrap and provide cushioning.

- Perfume bottle? Die cut gray board+velvet coated film, which looks beautiful and high-end.

- electronic component? Cowhide honeycomb board can perfectly fit electronic components and has strong shock absorption ability.

Partition boards can also become a part of brand display

For further processing of partitions, partitions can also provide your customers with a good unboxing experience, such as:

- High end feeling (black card+hot stamping)

- Printing brand logo

- Add patterns to enhance visual marketing elements

Real case: A makeup brand in the United States used black die-cutting partitions and gold hot stamping, and the unboxing video was shared more than twice as many times.

How to choose the appropriate type of divider for you?

Before designing your exclusive dividers, you need to consider the following questions:

- Is your product prone to breakage? Will they collide with each other?

- Do you need long-distance transportation? Will it stack? Should we go by air or sea?

- Does the divider require a brand logo? Or should we use a cheap white box?

Installation skills and precautions:

- Check the direction of the cardboard pattern. Vertical strength is better, suitable for stacking.

- Don’t be too tight or too loose. If the partition is too tight, it will affect the unboxing experience; If it is too loose, it may cause shaking and damage.

- Sample production: Product samples → CAD drawings → Die cutting samples → Strength testing → Batch production.

Cost optimization and environmental solutions

Want to save money and be environmentally friendly? You can do it this way:

- The outer box is made of three-layer cardboard, and the inner box is made of single-layer or two-layer gray board.

- Replace the foam separator with honeycomb kraft paper.

- Place the food grade moisture-proof partition board only on the top layer and apply a PE coating.

| Method | Cost Saving | Eco-Friendly | Practical Tip |

|---|---|---|---|

| Mixed Materials | Save 10–15% | ✔ | Use stronger outer layer, cost-saving inner layer |

| Foldable Sleeve Structure | Less manual labor | ✔ | One-piece wrap reduces packing steps |

| Kraft Honeycomb Board | Lower damage rate | ✔ | Recyclable and excellent shock resistance |

New trends in carton dividers in 2025

The packaging industry is constantly evolving, and dividers are becoming increasingly intelligent and aesthetically pleasing.

Latest developments:

- Die cutting and foam composite separation are popular in the beauty industry.

- Waterproof slots separate access to the prefabricated meal box market.

- CNC precision cutting honeycomb structure is applied to high-end electronic products.

Why it is important:

- Reduce returns and complaints caused by product damage.

- Improve the efficiency of automatic packing

- Enhance the brand’s first impression during unboxing

FAQs

Can I customize product size dividers?

Of course, XiangGe Package can provide you with customized structures and free die-cutting services.

Can cardboard dividers be recycled?

Kraft paper and gray board materials can be 100% recycled without the need for lamination or layering.

Where can I buy partition boards?

You can contact us as a packaging manufacturer that provides you with "complete packaging+insert board" services.

Conclusion

Core points review:

- The partition board is not only effective in separating products, but also the key to protecting them.

- Choosing the right partition structure can significantly reduce the probability of transportation damage.

- The selection of materials is not necessarily expensive, and scientific matching can also balance protection and cost.

- Customized structures can significantly enhance your customers’ unboxing experience and brand impression.

Next suggestion:

- List your product size and material.

- Determine your priority goals: protection, aesthetics, or cost savings.

- Apply for a sample partition board, test it first, and then place an order.

About XiangGe Package

We have been specializing in customized production of packaging boxes and internal structures for over 10 years, serving customers in countries such as Europe, America, Japan, and South Korea. From red wine packaging, perfume case, to precision electronic components, what we provide is not just a “plug board”, but an overall plan to effectively reduce the damage rate and improve the unpacking experience.

Do you need help designing a suitable partition structure for you? Contact us immediately.

Last update: August 2025

Recommended internal link: