Corrugated box manufacturer

- Custom any sizes at small, medium, flat, large, extra large.

- Multiple colored available: kraft, black, white, brown, pink, green.

- DIfferent paperboard optionals: single, double, triple walls.

- Suits for hat, pizza, fridge, wine, decorating uses.

What are corrugated packaging boxes benefits?

Excellent cushioning performance. The center is composed of U, V, and UV corrugations, creating a hollow structure that is approximately 60% hollow, effectively preventing vibration and impact during transport.

Lightweight. The corrugated boxes of the same size weighs only 1.5 times as much as a wooden box, making it easy to handle and store.

Low cost. Corrugated cardboard is made from straw pulp, wood pulp, or recycled cardboard, a readily available and abundant raw material. Its price is half that of a wooden box.

Widely applicable. Whether you’re using it for transportation or warehousing, XiangGe can customize it for you.

Environmentally friendly. Reusable and recyclable, it meets environmental standards and does not pollute the environment.

What is the difference between corrugated and cardboard boxes?

The main differences between corrugated and cardboard boxes lie in their structure, strength, and purpose:

Structure: The cardboard boxes are a single-layer thick cardboard box, essentially a flat sheet of pulp. Corrugated boxes consist of three layers: liner, core, and face paper.

Durability: Due to their multi-layer structure and core, corrugated boxes are stronger than standard cardboard boxes. Corrugated boxes are used for fragile or heavy items, while cardboard boxes are designed for lightweight packaging.

Purpose: Cardboard boxes are used for compact packaging. Corrugated boxes are the most commonly used packaging in transportation, warehousing, and logistics.

Custom corrugated boxes wholesale

Xiangge Packaging offers custom corrugated boxes with customized dimensions, thickness, weight, printing, and even separators, liners, and backing. All boxes are manufactured in Ningbo, China, where we leverage our comprehensive supply chain resources to offer prices up to 8% lower than competitive prices. Our goal is to become a one-stop wholesale provider of corrugated boxes and packaging.

Reverse Tuck End Box

It can be opened from the top or bottom, and can also pack heavier products

1-2-3 Bottom Box

You only need 3 simple steps to close it easily without letting the items fall out.

Custom corrugated packaging boxes optional

When choosing custom corrugated packaging boxes, you need to consider the level of product protection (weight, fragility, exposure), brand, and environmental protection. For high-value products, strong and thick corrugated boxes may be more suitable. Learn further packaging symbols guide.

- Type

- Materials

- Waveforms

- Size

Corrugated Box Types

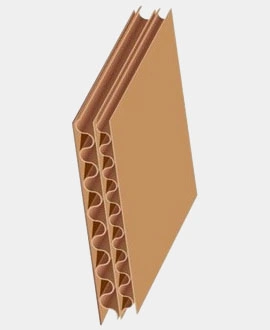

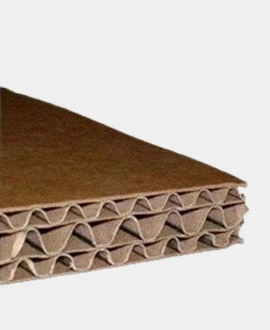

On the right are the common types of corrugated layers, 2 ply, 3 ply, 5 ply, and 7 ply corrugated boxes. they vary in thickness, shock absorption, and cushioning capabilities.

2 ply corrugated box

Simple structure, suitable for light cargo packaging.

3 ply corrugated box

Consisting of 2 sides and 1 corrugated core paper, it is suitable for medium and inner packaging.

5 ply corrugated box

Made from 2 layers of boxboard and 2 corrugated core paper and one layer of sandwich paper, suitable for packaging fragile products.

7 ply corrugated box

It is made of face, corrugated, core, corrugated, core, corrugated paper, and lining paper bonded together, and used for heavy goods package.

Paperboard Materials

The types of facings commonly used in corrugated liners include K paper, A paper, B paper, C paper, W paper (white paper) and 3 paper. Study more corrugated paper information.

| Paper Type | Also Called | Weight (g/m²) | Features |

|---|---|---|---|

| K Paper | Kraft Paper | 200–250 | Best quality, thickest, strong and durable |

| W Paper | White Paper | 125 | Smooth surface, great for printing |

| A Paper | Kraft Paper | 150–175 | Good quality, second to K paper, medium price |

| B Paper | — | 120–130 | Lower quality than A paper, used for standard corrugated box packaging |

| C Paper | — | 125–135 | More grass pulp, yellowish color, lower cost |

| 3 Paper | — | 100–150 | Lowest quality, thinnest, used as core/base paper in corrugated boards |

Waveforms of corrugated

There are 3 main waveforms on the right side of the corrugator: U, V and UV.

- U-shape: good elasticity, good adhesion, weak flat compression elasticity.

- V-shape: like a triangle, stands up well, poorly restored and pasted.

- UV-shape: high compression strength, we mostly use UV wave type corrugated.

Corrugated box sizes

Here is a list of some of the standard corrugated box sizes:

- 290 * 170 * 190mm, used for packing small pieces, decorative items, etc.

- 430 * 210 * 270mm, for shoes.

- 530 * 230 * 290mm, used for bags or large items.

Get corrugated storage boxes today

Fill in your basic information for the corrugated mailing boxes, and our team will contact and design within 24 hours.

Advantages and Disadvantages of Corrugated Boxes

Corrugated cardboard has become a mainstream packaging material due to its lightweight, low-cost, cushioning properties, and environmental friendliness. However, it suffers from poor moisture and water resistance.

Advantages:

- It absorbs external shocks well, effectively reducing damage to goods.

- It can be folded flat, reducing volume and thus lowering shipping costs.

- It prints well and absorbs ink easily, making it easy to print and promote.

Disadvantages:

- It has poor moisture resistance and softens easily due to moisture. Over time, its hardness and strength decrease.

- It has poor water and mildew resistance and is sensitive to moisture, making it susceptible to mold and deterioration.

At XiangGe, we know your product needs a strong box. That’s why we check every detail before it leaves our factory. Here’s how we make sure our corrugated boxes are strong, clean, and ready for shipping.

1. We Start with Good Paper

We choose high-quality kraft paper for every box. If the paper is too soft or thin, we don’t use it.

We match the right paper to your needs—strong for shipping, smooth for printing.

2. We Check the Flute

Flute is the wavy part inside the box. It gives the box its strength. We check the size and shape of the flute to make sure it fits your order. If the flute is crushed or not shaped well, we reject it.

3. We Look at the Box Surface

We check every box including: smooth surface, no bubbles, no wrinkles, clean printing, no smudge. If it doesn’t look good, it doesn’t pass.

4. We Do a Pressure Test

We press the box from the sides and top. If it dents too easily, it’s not strong enough. We also use machines to test the edge crush strength and burst strength. That’s how we know the box can handle stacking, shipping, and long trips.

5. We Test the Glue. We check if the box holds tight where it’s glued or stitched. If the corners open or the seam is loose, we fix it or toss it. Our team checks this by hand and with machines.

6. We Check for Moisture Protection

Some customers need water-resistant boxes. We test by dropping water on the surface.

Xiangge Packaging has fully automatic or semi-automatic production lines to meet different packaging orders and printing requirements.

Base Paper Preparation: Procurement of face paper, core paper, and separator paper are the primary materials used in production.

Corrugated Cardboard Production: The core paper is processed into corrugated sheets and bonded to the face paper with adhesive to create single-faced corrugated paper. This is then bonded to the intermediate separator paper to create multi-layer corrugated cardboard.

Cutting and Drying: After the corrugated cardboard is cut, a fan is used to remove paper scraps and ensure a clean surface. Heat drying is then performed to maintain a moisture content between 9% and 12%.

Creasing and Grooving: After creased by the vertical and horizontal creasing machines, the cardboard enters the printing press for grooves to prevent tearing and ensure product quality.

Printing and Coating: The designed pattern is printed on the printing press, followed by a coating of wear-resistant oil. Further drying is performed to dry the ink and coating, ensuring that the printed content is legible and wear-resistant.

Forming and Gluing: The cardboard enters the carton forming machine for gluing the side walls, or enters the stapling machine for stapling the side walls, forming the basic structure of the carton.

Packaging and Quality Inspection: After the corrugated boxes are formed, they enter the packaging machine for final packaging. Throughout the production process, our quality inspection department strictly controls every step, performing weight, edge pressure, and damage resistance tests to ensure that they meet your requirements.

How does XiangGe Package produce corrugated boxes

Why choose XiangGe as corrugated boxes supplier

Professional

We have been in the field of corrugated packaging boxes for 10 years and have a deep understanding of the packaging needs and differences of various industries, and are able to provide targeted solutions to ensure packaging effectiveness and protective functions.

Customized

According to your product characteristics and transportation needs, we provide personalized corrugated boxes solutions to enhance packages efficiency and brand image.

Efficiency

We have 5 sets of advanced automated equipment to meet your diversified and large-volume order needs, with delivery as fast as 3 days.

Quality assurance

Our QC team will strictly implement and check every procedure in the production process to ensure that every corrugated box meets the standard. In case of unqualified, we can return or exchange service, so you have no worries.

What are our clients saying

Since work with XiangGe cartons, the breakage rate of our corrugated boxes has been greatly reduced, and customer feedback has been very good.

E-commerce Manager

The corrugated boxes you customized are accurate in size and fit our parts perfectly, greatly improving our packaging efficiency.

Kylo james

Purchasing Manager

The quality of your corrugated boxes is stable and reliable, and the price is very competitive, making them an ideal choice for our export business.

General Manager

We have been cooperating for so long, and your company’s service has always been in place, delivery is on time, and communication is smooth, which makes us feel very relieved.

Supply Chain Director

Contact Us

We’d like to hear from you. Please complete your corrugated packaging box request form below, so we can respond to your enquiry.